Probably not very relevant given the large number of pics and sketches in there ? and wayyy out of my abilities anyway. There are some excellent CNC podcasts available, can’t remember the name, the one co-hosted by Winston for example

See if you can get Morgan Freeman.

Yup - at least for me I usually need to “see things” to really understand them. It’s nice when I don’t have to do the visualization work myself. Thank you!

-

@WillAdams

Do you think it would be worthwhile and possible to have living C3D threads dedicated to archiving and evaluating/ranking videos and podcasts?

Any sort of content related to CNC with Carbide 3D machines is welcome here.

While not ranking, I’ve been trying to keep up with #MaterialMonday at:

Evening @Julien

Seen one typo under troubleshooting & maintenance - “Crashing the mashine”

Every Good Read needs to know a little bit about the Author - I would love to see a little section about you, why you did this, and your journey from minnow to King frog of CNC

I know you don’t want to direct link in the V2 but i think an additional reading sheet / appendix would be worth while (i too am a 20 deep serial clicker Start at F&S end up at nema stepper motor micron accuracy lol) i would like to further back this up by my recent experience as a use case to why.

I was reading the F&S section and Tool paths and had my first epiphany (thanks for that DOC vs WOC) and there was a stand out quote you said

“If you go for narrow and deep (and you should!), given the small WOC values you will definitely need to take chip thinning into account.”

i found myself thinking why should i i didnt really get it etc but like most things i just go with it by applied knowledge differences. i.e. yours better than mine.

However as i was looking for the V2 link to the document i cam across the link to " The Definitive Talk on Adaptive Clearing in HSM" this 40 min Video + your document has warped me to new thinking and already reduced some of my tried and tested jobs by 15+mins. it has also solidified my experience and knowledge with the “i knew this but it had not clicked yet” if that makes sense

So as you can see from my real example if it was not for that chance link find, i would not be better off. So i would urge you to create as suggested an appendix / essential reading / viewing page to by digested at different pace to the main document.

So that is just my two pence worth

Again an excellent document Julien, if i can help with anything please let me know and i will do my best to assist you

Cheers

Jon

Thanks for spotting the typo (and in a title…if that is not “hiding in plain sight”…)

What your example is really telling me, is that there is are parts of the e-book where I drop a bit of information (or even opinion) without explaining enough.

But you guys will really make me reconsider providing a set of links / watchlist appendix…I guess we could do a quick poll here on the forum, figure out the top10 most helpful resources, and include that along with a brief description of why they matter.

10 posts were merged into an existing topic: Speeds, Feeds, Power, and Force (SFPF) Calculator History

This excellent e-book recommends a narrow (RDOC) and deep (ADOC) and my recent attempts have found this to be a very good strategy; however, when starting a pocket the first cut is always a slot with maximum RDOC and when coupled with deep ADOC this leads to a very large cut at the start of each pocket.

I’m using Carbide Create so, ramps and adaptive cutting are not options. What should I be doing?

We touched on this briefly in this post and the few following posts.

If you want/need to stay with CC, the (only?) option we were discussing that would work for pockets to “emulate” the benefits of helical ramping for cutting at large DOC, would be to:

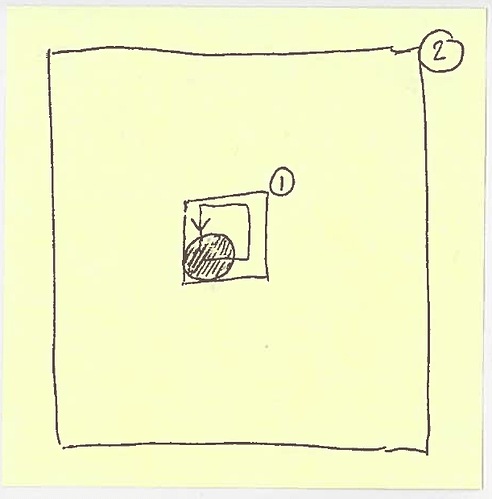

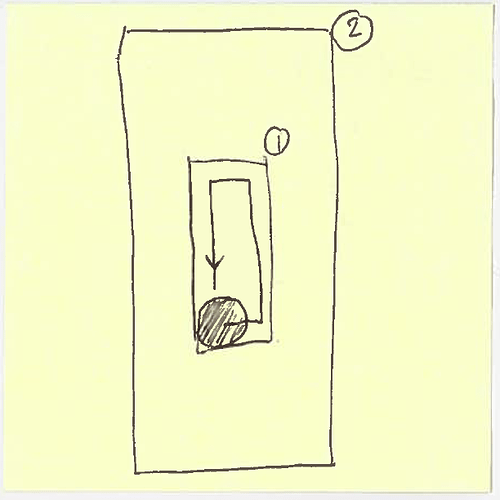

- define a much smaller profile (1) in the center of the large pocket you want to cut

- create a conservative/small depth per pass toolpath for that inner pocket, to cut that area down to full depth in small increments (i.e., the “usual” way). That would emulate the helical ramping to full depth.

- then create the narrow & deep toolpath you want for the main pocket (2), with depth per pass set to full depth (or whatever large DOC you want to use) and a small stepover, AND make sure CC generates a pocketing toolpath that will start in the center, where the first toolpath removed material already

That way, when running that second toolpath, the endmill will plunge to full depth (into air), then it will take a few turns in the air, avoiding any slotting/full tool engagement because by the time it starts actually cutting material, it will only be using the small stepover (low RDOC at full DOC) to cut into the walls.

Now, since CC adapts the toolpath to the shape of the pocket profile, for a rectangular pocket you would need to adapt the shape of that inner pocket accordindly, in fact it would need to match the trajectory followed by the endmill during those first few moves of the endmill in the second/main toolpath.

Now that I think of it, the “offset profile” feature would be perfect to do this for any arbitrary rectangular pocket. I’m not sure I’m being clear here, and this is all theory as I have not tested this (I mostly use VCarve and Fusion by now). If you are willing to test this approach and if it works for you, I could then include this tip in the ebook. Who knows, we might even convince the CC developer(s) to automate that behavior (though that would be a very convoluted workaround to just implementing…ramping  )

)

@Julien

Very well explained!

But also this highlights why people move away from using Carbide Create once they have learnt enough about good machining toolpath strategies that simply cannot be done easily with CC.

Less experienced people stick with Carbide Create and unwittingly, prematurely and extensively wear out their end mills and have a less than stellar experience.

IMO, there is so much basic stuff that Carbide3D (@robgrz) needs to fix or put into Carbide Create Basic before they launch the “PRO” version. Indeed, without these basics it could not be a “PRO” version anyway.

Getting good toolpath strategies with workable F&S is essential for newbies, occasional users and serious hobbiests alike as well as the other functionalities that have been requested and are still not here. I know they are working hard and have made some headway with CC but there is a long way to go to convince a serious hobbiest to spend money on it. Hopefully they will be up to this serious challenge!

If they could get CC Pro to have most of the functionality of V-carve Desktop without the 24”x24” limitation (to run on the XL and XXL ) and with true 3D capability at around $300 or so then they would have a winner.

Rant over… lol

Thanks! Sounds like the best plan is to accelerate my study of Fusion 360.

Unless I’m missing something, even the latest Vcarve Pro 10 doesn’t have the desired HEM strategies that Fusion provides and @Julien’s eloquently explained work-around addresses. ![]()

Fusion 360 is free for hobbyists, but has a bit of a learning curve. @wmoy has some nice videos showing how to use it with Shapeokos - here’s one of them.

True, but it does have a variety of ramping options, so even though you don’t get adaptive clearing, you can still adopt the “narrow & deep” approach for (regular) pocketing, without resorting to the manual workaround described above.

So, to each his own, it’s doable in CC (and looking at what @WillAdams can pull off in CC, I would say pretty much anything is technically doable in CC ![]() ), it’s easier in VCarve (but $$$), and it’s easiest/built-in in Fusion360 (learning curve + evil Autodesk corporation etc…)

), it’s easier in VCarve (but $$$), and it’s easiest/built-in in Fusion360 (learning curve + evil Autodesk corporation etc…)

While VCarve Pro does not have many capabilities that Fusion has like adaptive clearing, it also has many that Fusion doesn’t. A circular saw and a jigsaw are both useful in your shop, while each will cut wood they have their place just like these software, they each have their strengths and weaknesses.

Sorry, I can’t see how that works. Could you or @luc.onthego please provide a simple example?

“evil Autodesk corporation” ?

Do you trust Autodesk to provide Fusion 360 free to hobbyists forever? To me it seems like the drug dealer who gets you hooked and then starts charging you for the drugs. F360 is very powerful and I like using it, but I am just waiting for the day it is no longer free. A similar thing happened with Onshape, and I’m glad I didn’t get too far along with it before they changed the policy.

Thanks!

I’m actually hoping to do a finger/box joint layout which will only require one setup and two tools and be almost void free — we’ll see.

Yep, exactly what I meant. Fingers crossed, I enjoy the Fusion360 drug a little too much at this point.

Even competent “evil” corporations probably try to do what they perceive is best for their bottom lines. I can see where offering Fusion for free to hobbyists could do that.

Well I am a full on junkie lol