@ApolloCrowe Have you moved the charts somewhere else? The link seems to be broken: http://carbide3d.com/nomad/feedandspeed.html

Remove the .Html and add a forward slash.

@ApolloCrowe Not all heroes wear a cape, thanks Apollo!

Is it safe to assume that the feed and plunge rates are in [distance/min] units, as in [in/min] or [mm/min] ? Those seem awfully fast :S

Also what does DOC stand for?

thanks for the help in advance

The curly quotes are used instead of double primes to signify inches — see Shapeoko CNC Router, Rigid, Accurate, Reliable, and Affordable

DOC is Depth of Cut — from the glossary: Shapeoko CNC Router, Rigid, Accurate, Reliable, and Affordable

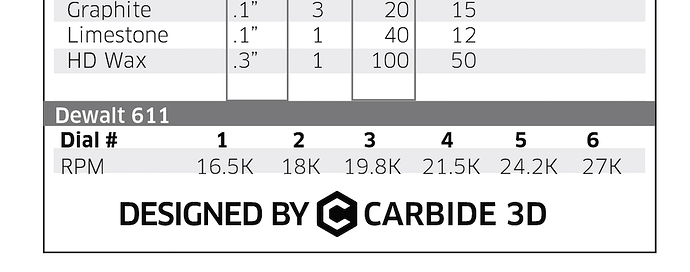

Depth of Cut is how deep the tool is under the surface of the material being cut. The depth of cut will determine the height of the chip produced. Typically, the depth of cut will be less than or equal to the diameter of the cutting tool. It takes more power to run a higher depth of cut and so slower feed rates and/or spindle speeds are usually necessary. The depth of cut is almost always less than the diameter of the cutter. Axial DOC is the depth specifically, radial DOC is the width of the tool which can be engaged in each pass.[37]

DOC: depth of cut. This has two contexts: the axial length of tool engaged in the material, and the radial engagement (which roughly corresponds in your toolpath generation as stepover). If not qualified, it is usually axial, with the radial specified by as a percent of the diameter rather than a measure (even though the path generation wants the measure). For example, if I just drop Z by 0.100", my axial depth of cut is 0.100". If I don’t change Z, but move the position (x-y) into the material 0.030", then my radial depth of cut is 0.030". For a 0.125" tool, this would be 24% engagement (24% of the diameter of the tool is in the work) The Carbide3d chart doesn’t separate these, but at the top of this page, @ApolloCrowe states that they are for 100% engagement, meaning the radial depth of cut is the tool diameter, and the chart refers to axial.

Plunge and feed are in distance/min. I believe the chart on the carbide3d site is inches per minute.

Thanks guys, super helpful.

I trust that the 1/8" speeds and feeds given for the Nomad will also work for the SO3? (albeit lighter than what the DWP611 spindle is really capable of?)

Are there any plans to release the feeds/speeds for the rest of your cutters for both machines? I’m really interested in seeing what I should be running the V-bits at in different materials to avoid burning up the tips…

@Kopah

What Router are you using?

I havent burned a v-bit yet, but I do try to keep my RPM in the lower range to avoid polishing the tool against the work.

The G-wizard is a good option for calculating speeds and feeds - I dont have a date for the next Carbide 3D tooling rates at the moment.

Outstanding chart!!! Wish I had found it last week before I burned up a bit. Oh well!

What are the RPM units. I have a DW 611.

Do you mean the RPM column in the chart at: http://carbide3d.com/shapeoko/feedandspeed/ ?

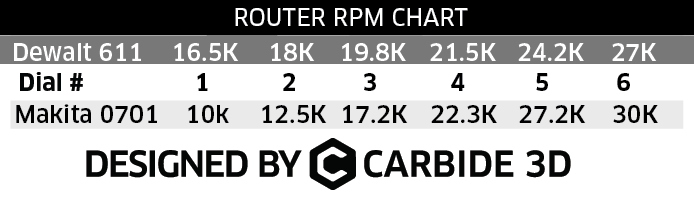

Scroll down to the bottom and it’ll break it out for the Dewalt (DWP) 611 by Dial # setting — for those who have a Makita, this can be translated using the RPM data listed at: http://www.shapeoko.com/wiki/index.php/Spindle_Options#100_to_999_Watts

In that chart ABS, for example, has an RPM of 1.5. Is that 15,000 or is some factor applied to the 1.5? Sorry, but 1.5 makes no sense to me. I can’t see how to apply it to a setting on my 611. I am clearly missing something.

I am unlikely to cut ABS, but if I can understand ABS, the rest will make sense, I think.

Thanks for your patience.

1.5 is the dial setting for a dewalt 611. If you want to know RPM you have to translate using that table at the bottom. So halfway between 16.5K and 18K.

Now I like the chart even better. Thanks, guys!

Maybe there is a complete sheet with metric units including Makita dials somewhere? Thank you

google mm to inches, there will be a calculator.

@nick made a Google sheet with metric. The link is earlier in this thread. You could add a Makita column to that pretty easily, I imagine.

yep, here is the link to the sheet: https://docs.google.com/spreadsheets/d/1W9qJwvAab4wG3X_33UDxojnT4U-X_ajUnJlPFmh2LtM/edit#gid=0