You mean, this one, earlier in this thread?

Link is broken. 404 error

New links:

I guess what I need is a chart that is comprehensive to all of the C3D endmills.

What I need is recommended feeds/speeds for #112 the .032" endmill. I have 1 left out of 3 as I broke the other two… Using a Dewalt my minimum is 16k spindle speed so I am a bit limited. Carbide Create shows the spindle speed to be ~5k. Make sense?

Sorry to be a bother. When I first looked at this post it didn’t show the whole thread which is why I asked. When I had clicked that first link I still couldn’t find it. So after I posted a reply voila, the whole thread appeared and I found the charts in question.

Unfortunately, we just don’t seem to have that information yet.

The Precise Bits folks know these sorts of small cutters best — they have a nice testing technique: http://www.precisebits.com/tutorials/calibrating_feeds_n_speeds.htm

but they’ve only published hard numbers on two materials:

- mother of pearl: http://www.precisebits.com/materials/ivory_shell/natural_shell.htm

- plastics: http://www.precisebits.com/materials/plastics/PMMA.htm

Doing some testing in pine using a 1/8" endmill has finally worked its way up to the top of my priority stack, and is what’s scheduled for this evening (then HDPE, then some tropical hardwoods) — so hopefully we can have some hard data presently.

Still trying to find an opensource spreadsheet / calculation system I like — pyspread hasn’t worked out as well as I was hoping, and the spreadsheet component for the jupyter notebook system has me baffled.

Haha sounds like the story of my life!  I have worked in IT since 2003 and currently run my own business so I totally understand. If there is anything I can do to help on my end I would be glad to where I can.

I have worked in IT since 2003 and currently run my own business so I totally understand. If there is anything I can do to help on my end I would be glad to where I can.

When it comes to this CNC stuff I am still a total noob. What I was trying to do is cut out a small image like this photo shows

The only problem is I wanted the cutouts to be inside a 140mm x 140mm square so naturally, I would need to use the smallest bit I have. But I will be patient as I am getting comfortable enough in using the larger bits in the sheet metal with my coated #102-Z and #201-Z.

My inclination for something that small and detailed would be to start w/ a V-carve, then finish up with the small endmill if needed — I did that for my locking register calipers: https://www.shapeoko.com/projects/project.php?id=154 and the additional detailing was nice.

As I said in the other thread, tell me what the material is, and I’ll run it through Gwizard and get you something better than nothing.

Hey sorry. I am using Aluminum 3003 grade. I will be switching to 5052 or possibly 6061. My provider said 5052 is the hardest while still allowing bending. Not sure if it matters when my stock is only .04" thick but I know 3003 gets gummy and I am really looking forward to not using that anymore.

I just tried creating a 2D contour with the V-carve bit and it churned out even more errors. I know I will eventually figure it out but I am still stuck with nothing.

Ok I am an idiot… Instead of doing a 2D contour I changed it to a 2D engrave using the chamfer and the simulation completed. Now comes the cut test!.. Sorry I am an idiot haha

I’ve run this a bunch of times through g-wizard, and I’m having trouble coming up with a solution that looks reasonable. I get 27 ipm, 13 plunge, at .015" stepover, which seems really fast. I’d try maybe 1/3 of that and speed up from there (so, about 10 feed and 4 ipm plunge respectively), at 27k rpm. I don’t like running the router at that speed. If you turn it down to 16k rpm, it recommends 16 and 8. Still seems high for a mill that small.

the http://carbide3d.com/nomad/feedandspeed/ is showing as 404 in my browser

Moved to:

I don’t suppose you’d be willing to export and share that tool library, would you? I’m working my way through the tutorials for F360 and I’m not sure if I’m understanding the feed&speed tab for setting up a new tool.

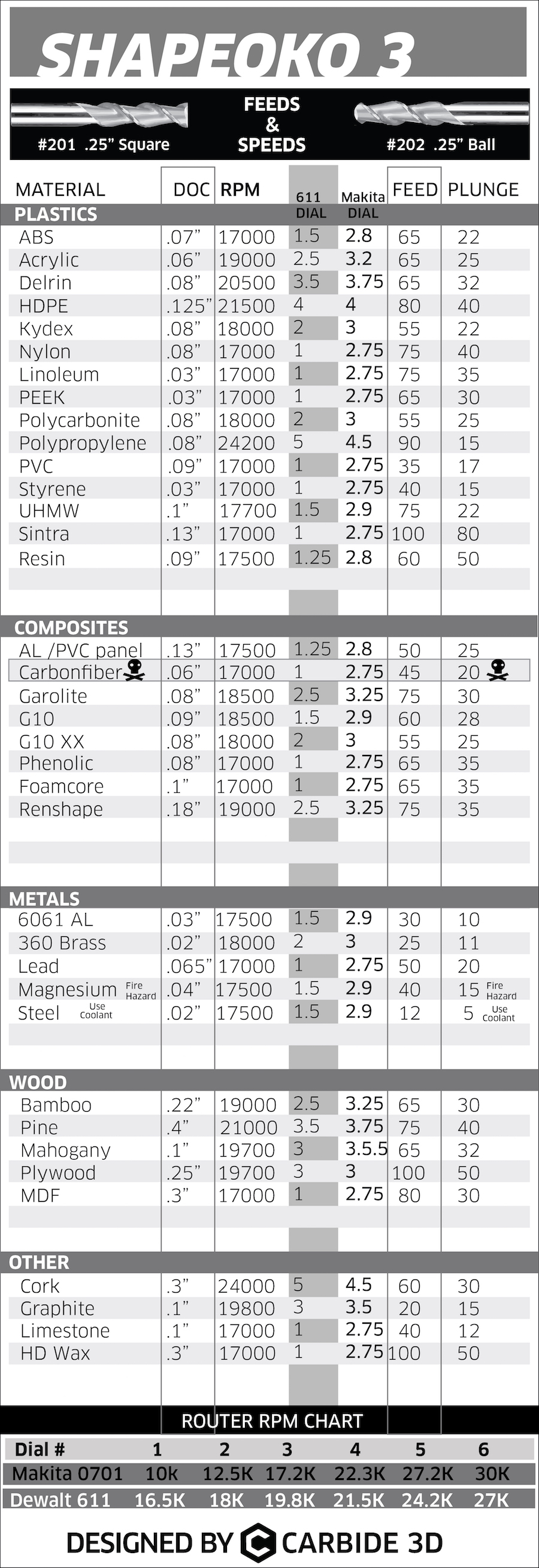

For example, Pine with a 1/4" flat cutter on the chart is:

DOC: .4

RPM: 21000

Feed: 75

Plunge: 40

In F360, I think that translates to:

Cuttting/Lead-in/Lead-out feedrate: all 75 in/min

Plunge Feedrate: 40 in/min

What about “Ramp Feedrate”… should that be 75in/min as well, or something slower?

And DOC comes into play when designing the toolpaths?

No problem, just PM me your email and I’ll the files and information.

So if i undersand, mutliply by 25.4 for convert to mm. Exemple 6061 : DOC = 0.254mm, Feed = 1066.8mm/min. Plunge = 381mm/min. This is good or not ?

For the rest of the world, here’s a link to a Google Sheets version of the Nomad chart with mm instead of inches!

I’m use G-Wizard for all my feeds and speed but still worry that the feedrate you get is the maximum rate for your tool. What happens when your machine slows down for a corner or Z axis change, aren’t we now making dust?

Cheers

Mike