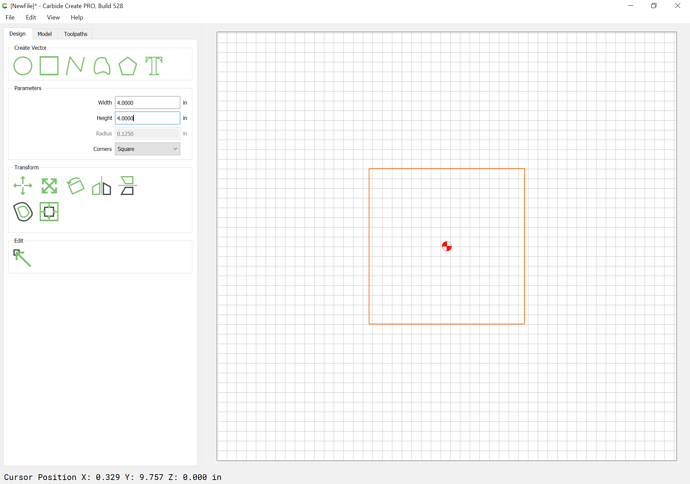

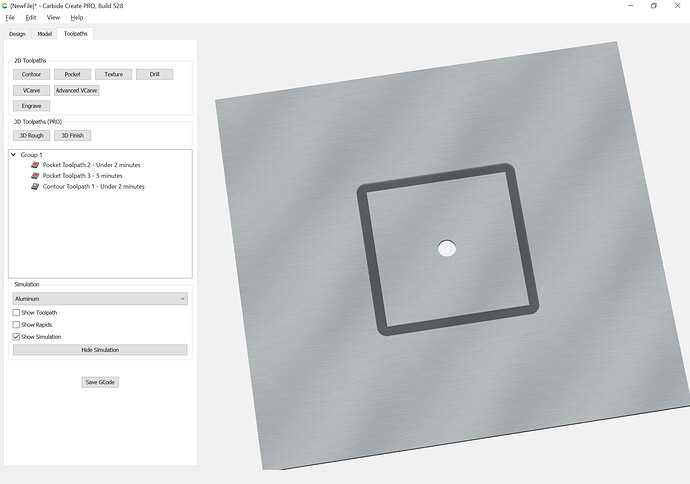

I would just draw up the geometry and assign the toolpath using the feeds and speeds in Carbide Create:

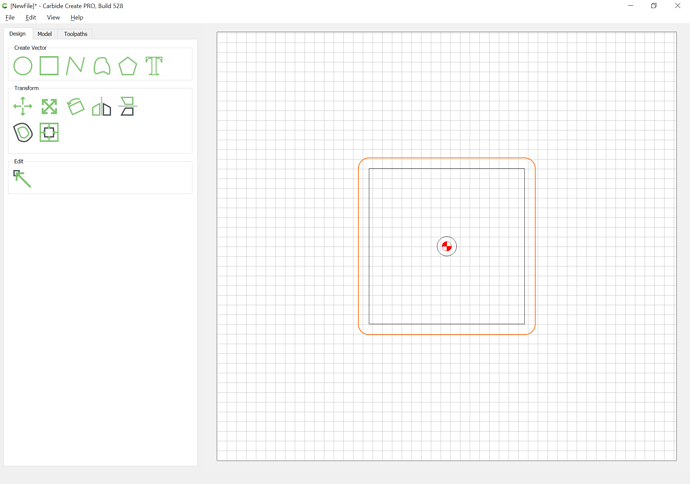

One consideration is that it’s better to cut as a pocket, than a narrow slot for a contour, so backup to the Design tab:

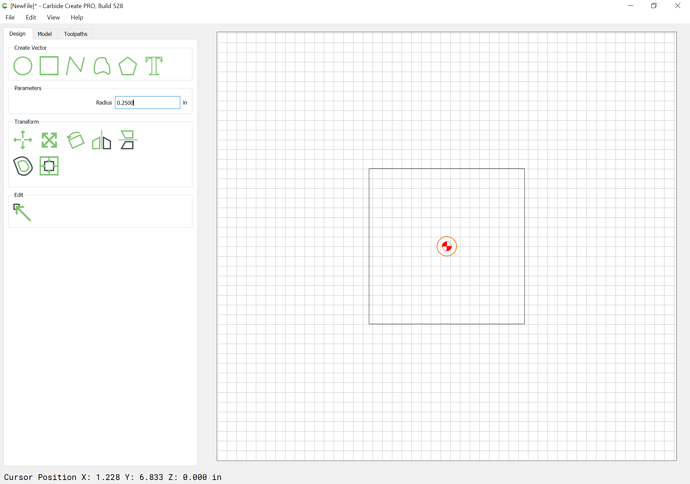

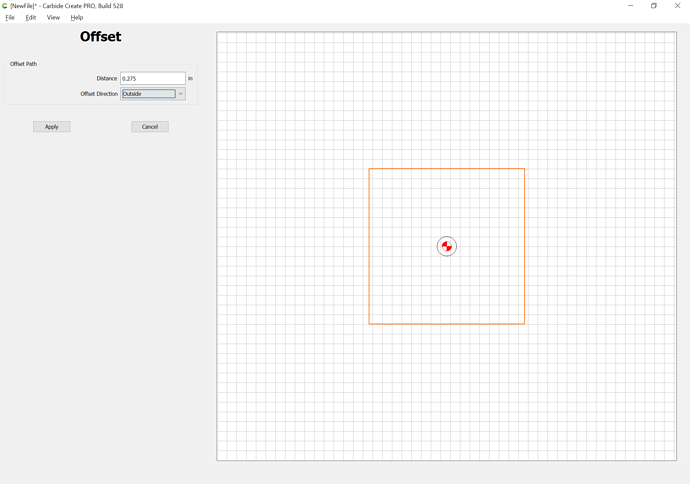

and offset the geometry to the outside by the endmill diameter plus 10%:

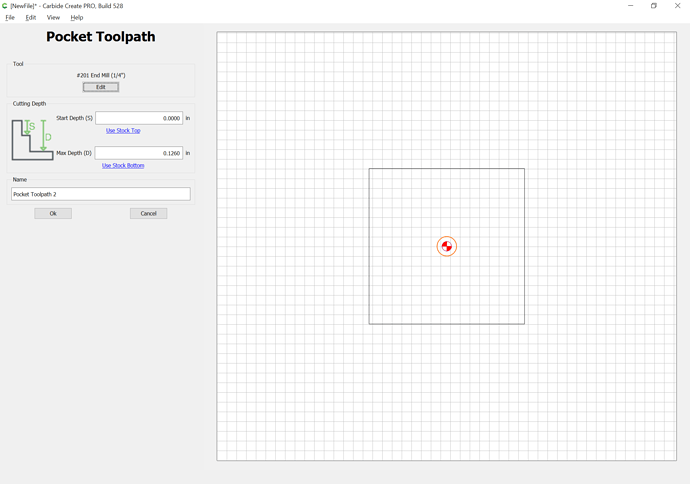

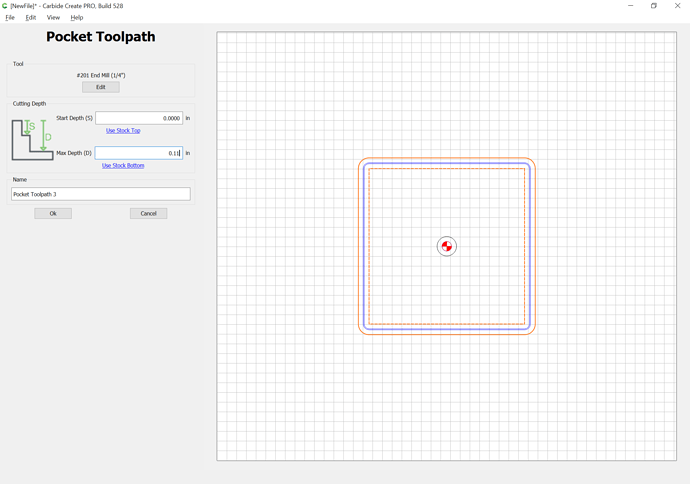

Then cut as a pocket down to tab depth or the penultimate pass:

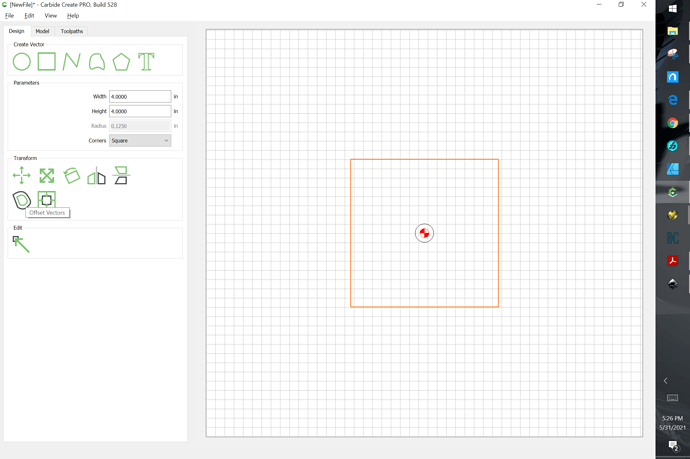

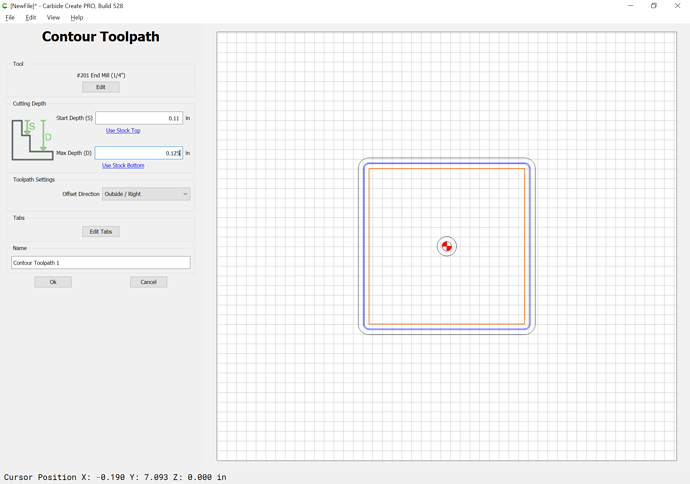

Then for the last pass select only the desired geometry:

(if not using a suitable workholding, assign tabs)