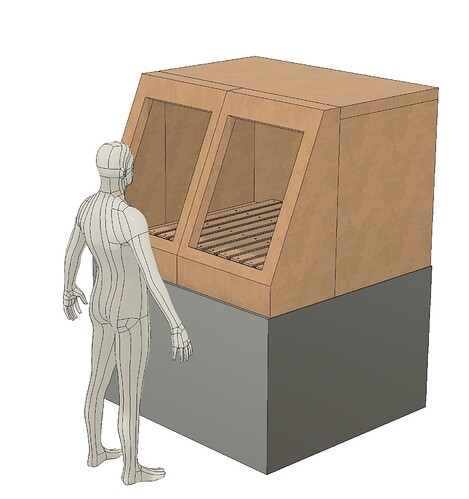

I think the doors look real cool in the new drawing, but I’ve been thinking about the Soss hinges you’re considering for the shape of door.

If you want to go this way, I encourage you to build a mock-up door and seeing how the hinges react before committing to the design.

Soss hinges (sausages) can be great, I’ve installed them on full sized doors and access panel-type doors before… they can be tricky to install, but they have their place… although what you’re talking about here is a very atypical installation. (more on that in a sec…)

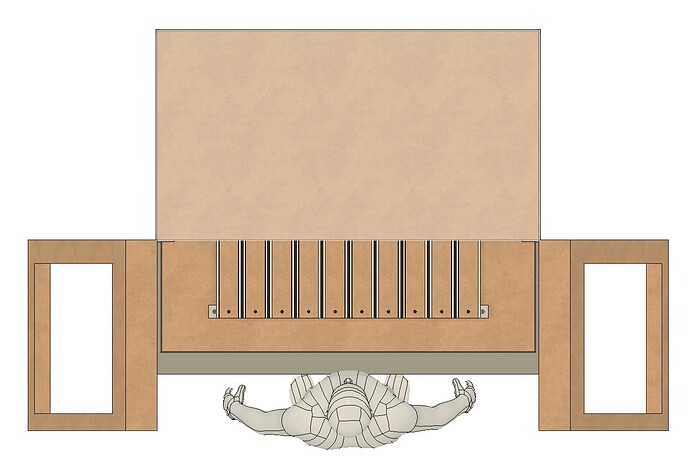

First and foremost - you’ll need to size them appropriately, so weight of the whole thing, and the thickness of your mounting stiles will need to be correctly sized. Refer to this chart if you haven’t seen this yet:

For example, for a 30 lb door, 30" wide, you’d be looking at two 1" hinges, or three 3/4" hinges… the larger you can go, the better.

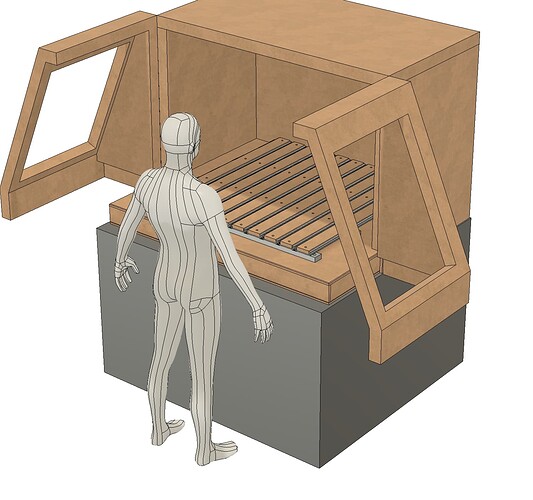

The atypical part of this install, and the part that concerns me… is that these doors will be putting at least two axes of stress on the hinges… A typical door leaf just has one dimension of stress- it pulls out away from the jamb.

Your door is a 3-dimensional object (I’m sorry, I don’t know the names for the exact forces applied), but the center of gravity of the doors is well off to the side of the plane of the hinges. Due to this shape, the doors will want to sag where they meet in the center of the box. How much, I really don’t know - but they will.

In your drawing, the bottoms of the doors will sweep over the tabletop, so this sag may interfere with the ability of the doors to close easily. Soss hinges have no adjustability. The only adjustability is what you can do with the mortise pocket.

So, I’d strongly recommend building a simulated mock-up door and hanging it as you intend before going forward with the whole thing. You may find that you need to upsize the door frame and stiles, upsize the hinges, or allow for larger gaps/reveals than you may expect.

If I may offer an alternative type of hinge… take a look at a geared continuous hinge, either butt mounted or face mounted to the outside of the door. Continuous gear hinges aren’t cheap, but the design gives a lot of rigidity to the pivot point, and I think they’d handle these doors well. You could probably get one hinge and cut it in half for both sides.

If you’re dead set on an invisible hinge, you might consider Tectus 3D hinges, which are like soss hinges but are adjustable in 3 dimensions. They’re pricey, but the adjustability can fix a lot of issues. I still don’t know how they’ll handle swinging this 3-dimensional shaped door, but it might save things in the long run if the doors begin to sag (or are a little off to begin with).

I hope this information is helpful. I’m certainly not trying to discourage you from this cool design - I’m just hoping it can save you some frustration, because it would suck to have to redo these doors after the enclosure is built.