I started using the key hole function I have a Frued bit and created a custom tool in CC.

Here is my custom tool database .csv file. This would only work for the Frued

Here is the Frued 70-104 Key Hole 1/4" shank key hole bit.

| number | vendor | model | URL | name | type | diameter | cornerradius | flutelength | shaftdiameter | angle | numflutes | stickout | coating | metric | notes | machine | material | plungerate | feedrate | rpm | depth | cutpower | finishallowance | 3dstepover | 3dfeedrate | 3drpm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 701 | Freud | 70-104 | Keyhole | end | 0.39 | 0 | 0.25 | 0.25 | 0 | 2 | 0 | Shapeoko | Hardwood | 10 | 60 | 16000 | 0.4375 | 0 | 60 | 16000 |

Here is a file that I used to create some key holes.

cigar_store_keyhole.c2d (44 KB)

In the file you will see three circles and that is where the key hole bit plunges in. then it goes forward then retreats and comes out the entry plunge.

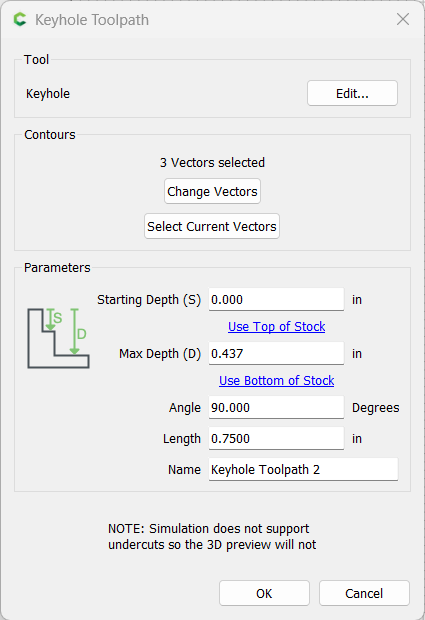

If you look at the simulation it looks like the bit plunges and goes forward and does not show the smaller diameter of the router bit making the key hole shape. Not sure which version of v7 I created the file in. The simulation is limited by the largest diameter of the bit to show in the simulation,

Here is the key hole tool path. The calculation is how big your big diameter is and the tool was created to have a depth of cut so the big diameter plunges down and then goes forward, reverses and comes back out the original plunge hole.