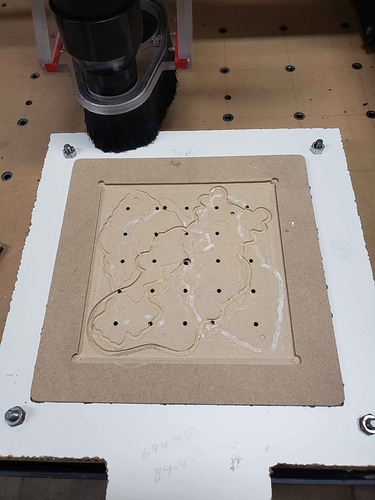

On of the justifications for getting my Shapeoko was to cut out Christmas Ornaments for the wife. She Tole paints and every year she does personalized ornaments for all the grandkids, nieces, nephews and some to sell at craft shows. This year she asked for a total of 40 to be cut. It takes as long to clamp as to cut, here is my solution.

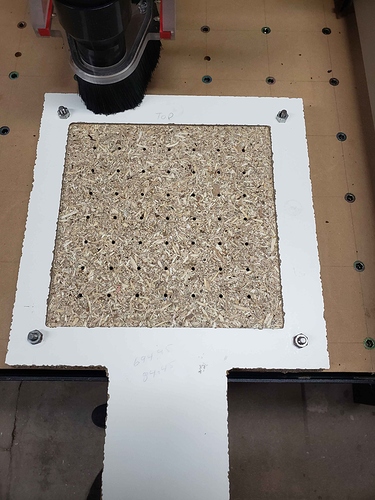

Two layers of 5/8 particle board, both have slots cut in them with 90 degree rotation top/bottom. Holes then down thru top to internal air channel slots, leaving material to support the load. The square sticking out the bottom is the attachment point for a shop vac. There is an 8” pocket to locate another MDF board where the blank sits.

I did it this way so I don’t have to worry about resurfacing the vacuum table as it is not the wear item, I can also change the size of the blank easily. I use 1/8" material I get from a local cabinet shop, they throw out lots of cabinets back blanks, some will have splits, some boot prints others seem to be like new, I trim around any defects.

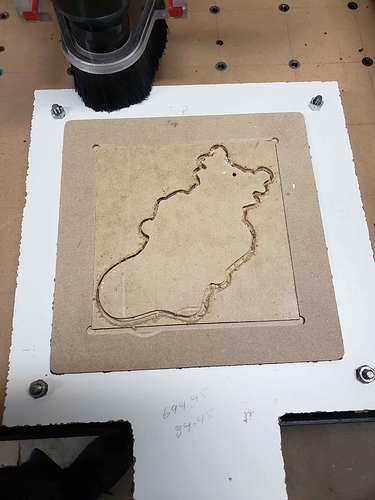

The final result, seems to work fine. I can not move blanks when vacuum is running and it even holds firm when I did get waste pried off.