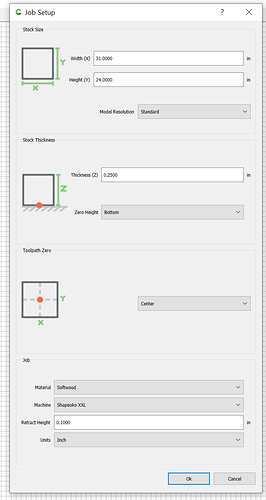

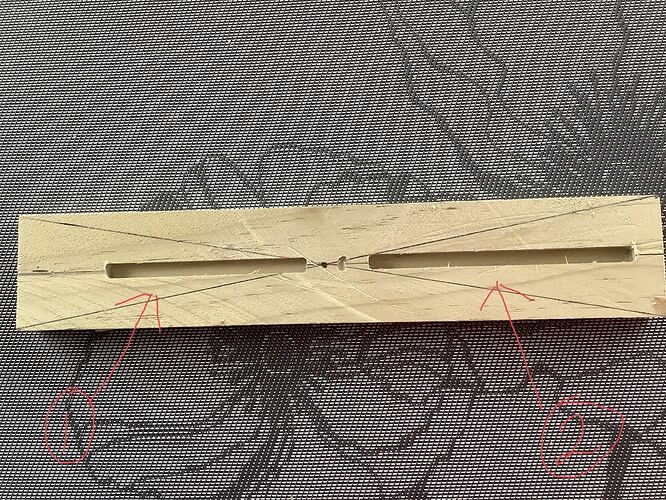

I have little issue for the life of me I can seem to solve,I have a 6mm slot cut in the wood and it is 4mm off centre in both directions,using CC and rechecking sizes and centres on CC all appears OK,centre’s are all in line.Stock size is all as I set up.Using the bit zero and setter.Any help would be appreciated.

If it must be centered, usually the best thing to do is to zero at center of stock. On your part you’d draw two diagonal lines to find center, and you’d use that zero setting in Carbide Create as well. That way your geometry is centered on the stock even if scaling is a bit off.

The usual ask here is to share your *.c2d file for a quick review, but we don’t have your stock to measure against so will have to trust you on that. You can also run some calibration test to make sure your axis are scaled properly, though this seems more like a centering issue than a scale issue given your slot dimensions were otherwise satisfactory.

Hi Dan,the slot is perfect,depth is perfect,I will try the centre as a start point as you say to see if that helps

@theworkshope’s suggestion is great and is usually more “robust” to user errors (since it basically makes things indepedent of the stock size and how accurately it was measured/entered), still you should be able to use lower-left corner as toolpath zero: if you feel like investigating what is going on, indeed upload your c2d file and generated G-code file here for a look, and tell us what the distance is between the left edge of the stock and the left edge of the slot, on that picture.

It has suddenly dawned on me my other items I have been carving out of oversized pieces of wood have always cut to one side more than the left side,it has not worried me till this issue.

Stock size is 250 by 46 and the distance to slot on left side is 26 and the right side is 23.5.The other sides are 18 and 22.Depths and length of slot are perfect.

I will load the files in the morning as I am on an I pad and the I Mac is in the shed with the Shapeoko.

If this is a BitZero v1, perhaps it cannot calculate the correct offsets for X&Y with the size endmill you are using?

My understanding is that it doesn’t work properly with any size endmill, which is why BitZero v2 has the hole to help calculate this.

Yes it is the first version,as I say the depth of cut is perfect.

If you are cutting on oversized pieces, cut it to finished size with the machine. This way it will have to be centered. This will tell you if your design was off or if the machine is off.

Or am I misunderstanding what you wrote?

Michael,up to now I have been cutting oversized stock and nor too worried about when the cut was but this piece needs to be fairly accurate,in a little while I am going to try as Dan suggested

Hi all,have done the test as Dan suggested and on the opposite side of centre done one with the zero.

As you can see with cut one it is on the money,on cut two it is so close I am very happy with it.So it may be me as human error,prior to this I have not set the tool in carbide motion,it defaults to the 1/4 inch.This time I set it for 1/8 inch.Would this be my problem???

When the edge of the tool contacts the Bit Zero Carbide motion needs to shift the detected position by the defined tool radius for the zero(center of the endmill) to be in the correct position. If you used Bit Zero with the wrong tool definition the X&Y zeros would be shifted by the difference in the tool radii.

This topic was automatically closed after 30 days. New replies are no longer allowed.