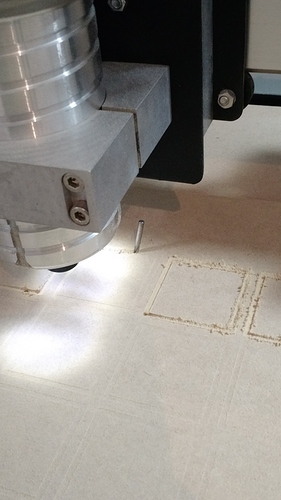

During a job and after just the first passes the Z axis went almost all the way down. It happened couple of seconds after a pause / resume on CM.

Is the second time it happened to me. First time it went down even through the waste board (mill bit broken of course). Don’t remember if the first time was after a pause / resume but it might have been.

In both cases I started again the project and using the same g-code file (generated by carbide create) everything went fine.

Anyone with the same problem?

Thanks

Am I the only one with that problem?

I am so afraid to pause and resume…

It’s a new one to me, unless the problem is the belt skipping.

Please contact support@carbide3d.com and send them the file for testing.

It just happened again

the bit went down almost 10 mm into the stock (MDF) !!

How can I check if it is belt skipping?

I don’t think is the file (which is very simple, just cutting squares)…

It must be hardware related or some sort of communication problem…

Thanks

jbaez-

Yes, please email support@carbide3d.com

Additionally, let us know when your avaialble for a skype or phone call.

We will figure this out.

I would check your z-axis pulley. At times even if spins freely under normal operation it can get stuck if it is too close to the stepper or there are defects in the pulley. Mine had a slightly oblong hole in the center which caused it to walk down the stepper shaft and eventually it dug into the face of the stepper and would get stuck periodically.

I replaced my pulley and it worked perfectly afterwards.

Thank you for the tip @daveo1984, I think my problem was the belt. I tighted and is working much better. I will keep and eye on the pulley. One of the problem I did have when assembling the z plate were the washers, they were very un-regular on thickness.