When trying to run the “coaster project” with even just a simple square cut, the spindle raises then runs to the back of the machine and stays there. It is not the homing position. It just goes straight back along the Y-axis from the zero position that I set. If I click on Run again from this position, it moves forward to the original zero position, lowers slightly, raises again and returns to the same position in the back as before.

What am I doing wrong??

Please post your .c2d file, generated G-Code and step-by-step notes on how you are securing your stock and setting zero relative to it.

Coaster.c2d (3.8 KB) Coaster.nc (100 Bytes)

I’m attaching stock and setting zero as described in the Coaster Project document…

Initializing machine

Jogging to beginning location - front left corner or material

Set Zero

Zero All

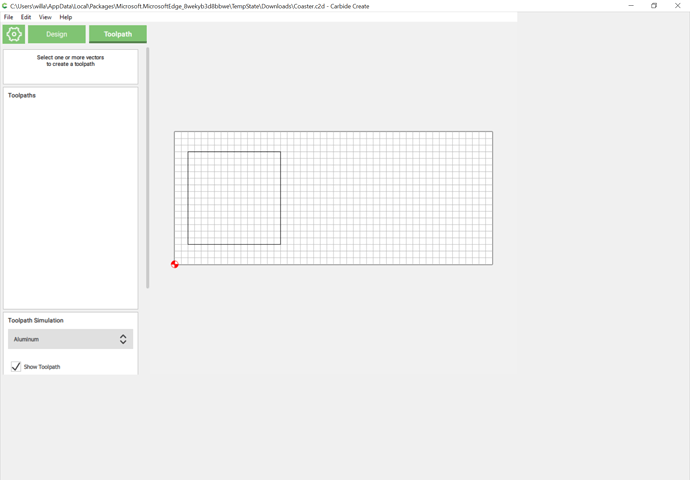

Your toolpath is empty (ish).

G21

G90

G0X0.000Y0.000Z12.700

G0Z12.700

M5

M30

It just tells the machine to go to XY zero, lift to 1/2" on Z and then it’s done.

EDIT: I don’t know why it moves straight back on the Y when done. I thought Motion sent it home. What version of Motion are you using?

You don’t have any toolpaths:

Please see: https://docs.carbide3d.com/assembly/carbidecreate/video-tutorials/#toolpaths and https://docs.carbide3d.com/assembly/carbidecreate/video-tutorials/#saving-and-simulation

CM will send the spindle at the back at the end of a job not at home.

Resolved. Complete newbie mistake. Didn’t create toolpath info in CC. Thanks to everyone for their help.

Well, all issues are explained then.

Has it always done that? I thought it went home at one point.

I think the older versions used to go home and if my memory serves me it changed when there was a development push for CM last year.

Correct, I think it was somewhere in the CM4 series that the interpretation of M30 was changed from diagonal move back to machine origin/home to straight move to rear of machine — my assumption is this was done so as to be more predictable and less likely to clip a clamp at a corner of the stock.

Yep, that happened to me, it was difficult to predict where the machine would pick-up go to safe height and move to the back. Now that I think about it, it was probably because the spindle did not retract all the way before homing. On the plus side, there may be a lot of wasted time to go home compared to going to the back if you are just changing endmill (when you don’t have a BitSetter) or changing the workpiece before pressing start without re-zeroing.

Lots of wasted time. Damn, I wish there was an option for that location somewhere.

What about using an M2 instead?

If the M2 doesn’t have the same behavior,

Along with a G28 or G30 (or a G53 location) would give you any location you want.

This topic was automatically closed after 30 days. New replies are no longer allowed.