I followed the guide about squaring my new XXL. Got the Y plates that attach to the X rail so they both contact the end plates perfectly and tightend everything down. Then checked again.

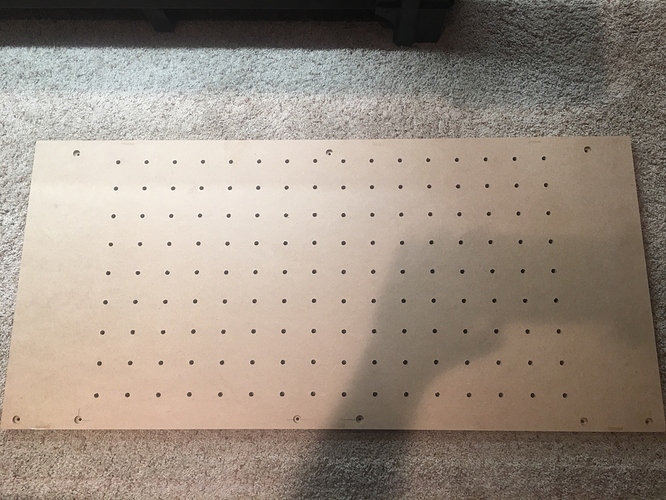

I then milled my back and front baseboards with 2 inch on center holes (using the method of placing 1 of 2 baseboards on top of he other)

The real failure I guess was not milling a test board first. The problem is the entire pattern is rotated with respect to the board edges. The lower left hole is about 2mm lower than the lower right hole. Also the upper left hole is closer to the left edge than the lower left.

Before I started I triple checked that the MDF baseboard edge was the same distance from the front end plates, on both corners.

The only thing I can figure is the Y axis rails are skewed, and not perpendicular to the X rails, despite following the checks in the guide. Does this sound like the only possible cause? Any other possible causes? Like maybe using a framing square to check things. When I put the CNC together I thought about doing that but didnt see any obvious places to place the square.

Thanks for any ideas while I ponder more while away for a few days camping.