Yeah, it’s confusing how Carbide 3D allows things to interact. I started on a step-by-step tutorial, but then got stuck and deleted the text/screengrabs.

Hey Michael, could you send me the file for this?

Thanks

Andrew

It’s available on Cutrocket:

Hey Will. That’s where I got it from, but it’s a vectric file and CC won’t open it.

Hope this helps

Step by step video up to tool path setting

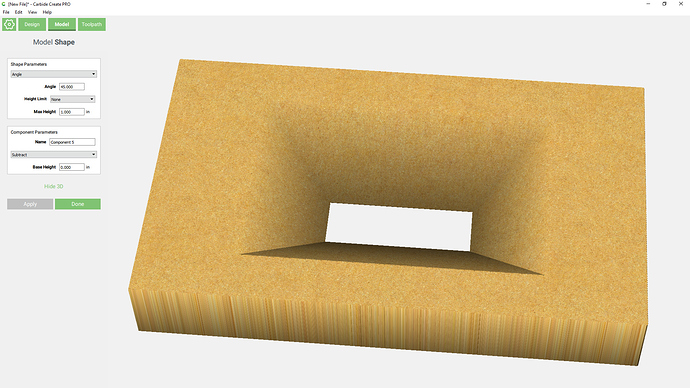

with Outer Box selected. - click 3d toolpath.

stepover set to .063 for roughing

same process but stepover st to .015 for smoother detail.

I tried recording this but everytime I set toolpath or simulate the windows screen capture times out.

link to .c2d file

https://drive.google.com/file/d/1krtS2t2n26dpKm8c7yRLlRGlg9fVKzic/view?usp=sharing

This was very helpful! Thanks so much for taking the time, really appreciate it.

It was my pleasure.

And thank you for thanking me…

Here’s another quick video on a different version.

Just adds two components,

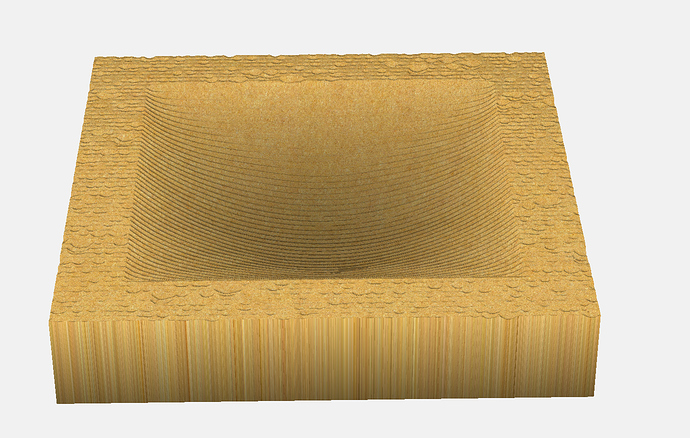

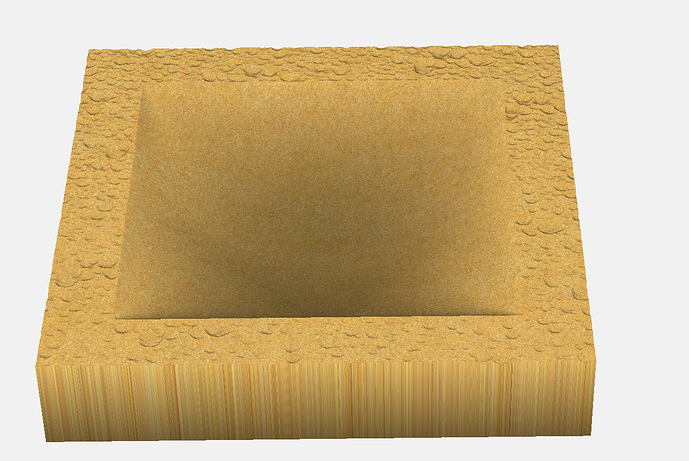

But the order inwhich you add 3D profiles really matters in determining the final outcome.

So we deleted the rounded pocket and went from there.

If we just try adding angled pockets to file above the outcome is totally different even though all components are identical.

This can be addressed without deleting components but for simplicty we will just delete for now

Again, really cool. I managed to carve the tray based on what

you sent me yesterday, and I’ll probably do a thicker one. But I also like this one you did with the shape at the bottom.Thanks!

Andrew

Nice, that looks great.

If you go thicker for the base, you can increase the degree of the angle of the round pocket.

Same for the angled pockets in the second tray.

It was at 45- A higher number will scoop it out more.

If we went to 50 with the stock at .75" it would have eaten through the bottom according to the rendering.

Again that looks awesome.

Glad it’s working out for you.

Just to have an idea of the toolpaths, how long did it take for this? Do toolpaths look efficient or kind of random?

yes, your right, was reaaly out of it. still am. theyve got me on crazy meds in here.

thanks

EDIT

I suppose one should stay off Internet for atleast a few hours after General Anesthesia

I’m a little late to the party on this one, but I just threw a screencast and machining video together to show everyone how I would go about making this in CC Pro and cutting it on the Shapeoko.

The screencast portion is pretty long (17 minutes) - but shows my entire process for designing this part. Basically I was pretending like someone was sitting next to me and I was showing them every single step of the process.

Project Files Here: https://cutrocket.com/p/5d2677ab45a13/

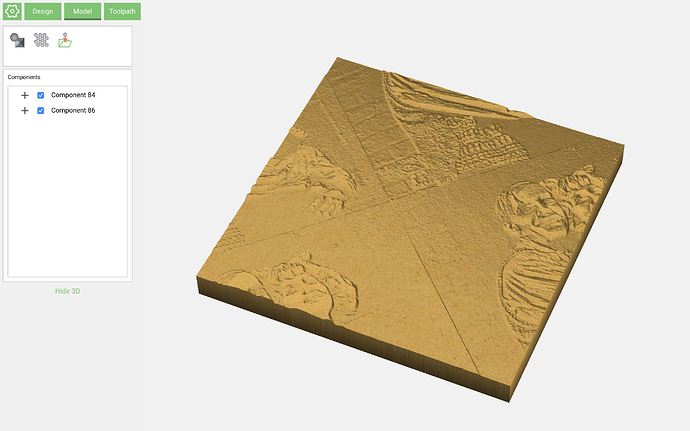

Hey Edward, thanks for doing this tutorial. It really starts to open up what this CC pro can do. Speaking of that, when I was messing around with border textures, I tried a photo to see what that would look like. I then realized that it would be cool to be able to carve a photo–is this possible? The border import does this, is there a way to centre the picture to get all of it, rather than broken up? It would be a really cool feature, although this picture would take about 18 hours to get fine detail…still with simpler pictures it would be cool. Just a thought.

I agree that the import of images to carve, not as border would be an excellent feature and probably trivial at this point.

That’ll be in 414 when it comes out

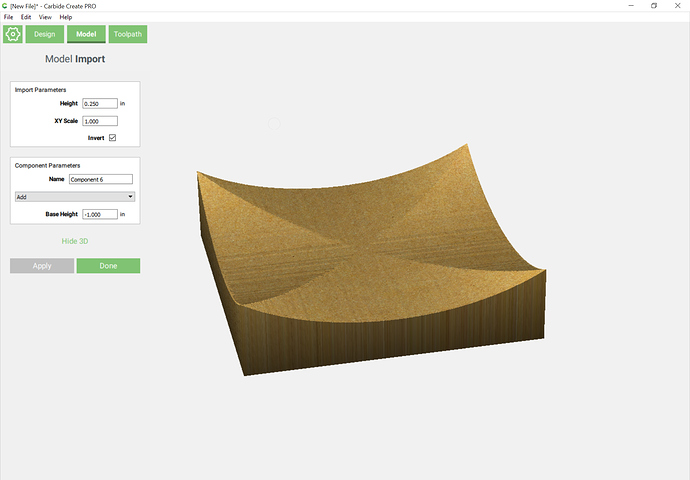

The new 414 is able to import this:

to make the shape which previously didn’t seem feasible to make:

Hope it helps!

Haha… well done! But how did you make that image?

I created one part in Carbide Create Pro, exported it as a PNG, then composited it in a pixel editor.

This feature looks to have a lot of possibilities — basically you can cut any pixel image, and draw up pretty much anything which can then be cut out using the toolpath options.

Unfortunately, I can’t work up toolpath options for a couple of the joinery ideas I have, so I’m back to trying to hand-program toolpaths for them.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.