I plan on installing them this weekend, any specific testing you looking for?

Mainly just fit and finish. Maybe info on if you see any differences in cut/motion quality

Well kevlar belt installation was straight forward, I did notice while tuning steps per unit, it was lower than the standard 1016 steps/in (40/mm) @ ~1014 steps, while my fiberglass belts were higher (~1018 steps).

Sadly I didn’t get far in cutting, troubleshooting the first job resulted in finding a cracked wheel, don’t think I can blame the kevlar belt though

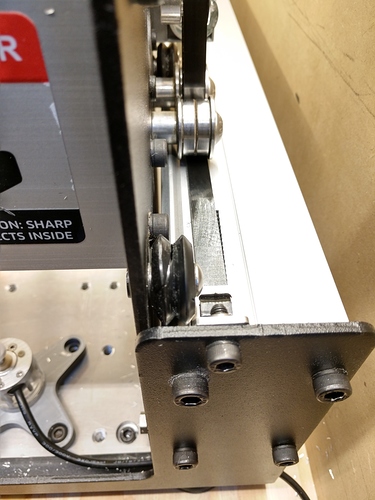

Kevlar belt along side cracked wheel

Hey is that a tool length probe I see? Little off topic but where did you get it and how do you have it set up?

Bad timing on the v wheel, I’ve been lucky with mine, though I do have a full set spare

Hey is that a tool length probe I see? Little off topic but where did you get it and how do you have it set up?

It is a Vers TSm. Kind of got it on impulse, as it is at a competitive price for a kinematic probe, and was on sale at the time (holidays).

I had just installed it along with the belts and among other things (like v-wheels ![]() ), so haven’t used it in practice yet. I use Mach4, so I have it connected to Probe 4 (G31.3) with a tool change script in Lua, sorry Grbl folks.

), so haven’t used it in practice yet. I use Mach4, so I have it connected to Probe 4 (G31.3) with a tool change script in Lua, sorry Grbl folks.

Could get Grbl to work with one as well, just might require additional electronic components, if you also use a touch probe. Along with a macro/script-able G-Code sender.

Bad timing on the v wheel, I’ve been lucky with mine, though I do have a full set spare

Yeah, these were actually replacements themselves, so will probably swap the one to an old one tonight for now.

Figured out how to embed vids. 1000ipm

Been a few months – how’s everybody getting on with their steel belts?

Extra rigidity confirmed? Any breaks? Wear and tear on the motor shafts?

On my side no break nor any side of wear on the belts or pulleys, and still very happy with them in general. I did not quantify the extra rigidity, I’m just happy that they seem to keep their tensioning for a long time (I did not touch them since January and they are still guitar string tight).

Yep, mine are doing great too. Tension still where I put it to. I upped my accelerations by 50% with no issues.

Just like Jonathan, I have increased stepper acceleration and also upped my max travel speed and they seem to be doing great. The faster rapid movements have cut down on machining time by a considerable amount. Mine have only been on for about 3 months, but they show no sign of losing tension. On the subject of belt tension, has anyone figured out a better bracket or assembly method to make it less difficult to adjust tension? right now its kind of a pain.

I have heard of people adding one long bolt instead of two tiny ones to make it easier. I have the first model Shapeoko 3 where I can loosen the motor mount and adjust that to tension the belts, which is easier than dealing with 2 tiny nuts and bolts.

yeah, I have replaced the front two bolts with longer ones to make tightening a smidge easier, but it seems janky to me cause your fighting the angle bracket wanting to come out of square while tightening.

Steel has been Real

Running them on two machines without issues and holding sub 0.005 tolerances easily.

They should actually be easier to tension because they stretch less and its easier to start the bolt. To stop bracket rotation, use a crescent wrench to hold it while final torquing.

Guess I should stop hesitating then!

Lots (all?) of HDZ users in here – but anyone find 6mm belts for the z-axis or is that ill-advised?

I was thinking the same thing while contemplating changing my belts. There has to be a better way… ![]()

There were a number of different ideas tried early on. See: https://wiki.shapeoko.com/index.php/Belt_Anchors

I recently discovered that my left side y-axis belt has snapped 1 of the 6 steel wires and besides having to tighten the belt some it is causing no issues (that stick out worse than my current tramming/collet run-out issues). The fiberglass ones started to show issues after a couple crashes while learning the machine. Like an idiot, I forgot to order more steel core belts once I decided I was happy with them. Oh well, I am about to tear the whole thing down to move it and my dust collector across my shop and hopefully throw on an hdz along with some other goodies. New belts and backups should be here by then. Overall, I am still super happy to have made the switch even with the premature failure. It was probably due to my “hulk smash” mentality when putting stuff together or a tiny defect on that one steel wire.

which belts did you buy? link?

https://www.amazon.com/dp/B07MWDWCLZ/ref=biss_dp_t_asn

I bought them by the meter to try them out. I would suggest buying a bulk roll to save a few dollars.