So the other day I was having issues with my Z skipping. After quite a bit of troubleshooting and help from several people on these forums it was determined that the issue was the bristles on Sweepy were too stiff. When my Shapeoko would do a plunge straight down the bristles would put up a lot of resistance which would cause the skip. So I started to look for replacements.

After searching around I found several places where people were making their own custom dust boots and used craft foam for the bristles. Could it be that simple and that inexpensive? So last night I went by a craft supply store and purchased some 1/8th inch craft foam for a dollar (USD). After about ten short minutes I had fully replaced my bristles with foam.

Here is the steps I took to make the new Bristles:

- Remove Sweepy’s Bristles

- Use the bristles at a template to cut a strip of foam, 1 Sweepy Bristles long by 2 Sweep Bristles wide:

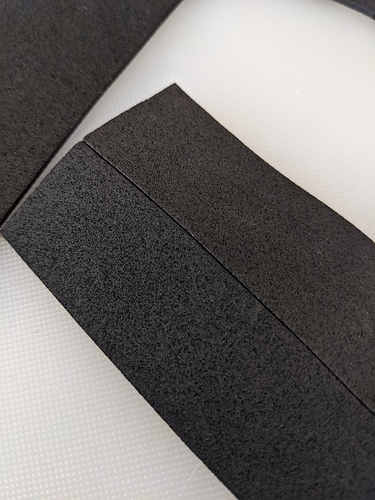

- Lightly score the back side of the foam down the middle. DO NOT CUT THROUGH THE FOAM!:

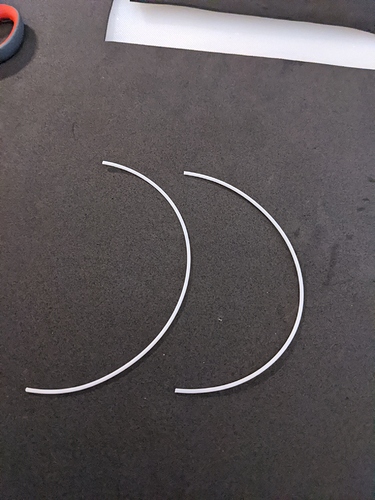

- Cut two pieces of 1.75mm 3D printer filament (you can also use wire of the appropriate diameter) as long as your Sweepy Bristles:

- Flip the foam over so that your score line is facing down and fold it over one of the lengths of 3D Printer filament.

- Loop the foam and filament into a circle.

- Line the circle up to the grove in the lower half of Sweepy.

- Using a small flat blade screw driver push the 3D printer filament into the grove all the way around Sweepy’s lower half. At this point it should stay in on its own, but a slight tug will take it back out.

- Take the second length of 3D printer filament and put it in between the two layers of foam, on top of the first piece.

- Use the screw driver to jam this piece into the grove as well. This might take several passes around the circle to get it fully seated. The foam should now be secure. You can still pull it out if you tug.

- Using scissors cut flaps into the craft foam about 3/16th of an inch wide all around the circle on both layers.

You should end up with something like this:

I have read reports that these types of foam bristles can be too good and form a tight seal. If that is the case you want to thin them out by cutting every fourth flap out. You need air moving for your vacuum to actually suck up the dust.

Please note that I have yet to test my Sweepy mod as I am currently modding my Mikita Brushless Router.

EDIT: I meant to take more pictures of this, but putting the filament in is kind of a two hand job.