Like Arnold said, “I’ll (the problem) be back!” ![]()

I have been an electronics technician, field engineer, systems support engineer and certified systems administrator. So I have an extensive background in electronics and electrical problems. There is thing called the critical need sensor. The more critical the need the more likely for an outage.

I recently bought a crimping tool from Amazon. For most of my career I used those cheap sheet metal crimpers. This ratcheting tool is way beyond those cheap crimping pliers. Even though I had been doing this work for so long I watched a video on youtube that taught me something about crimping connectors. You never know what you dont know. Even though your work is done it might be helpful for others or use in the future.

In my case for the connectors that I used, there were no crimped connections. The wire is 6 gauge power in wire from the main breaker box to the secondary breaker box. The house has the main power wires coming from the power pole. Then my power comes off of a 100 double pull breaker. Then the wire runs back outside and underground all the way back 150 yards to my shop.

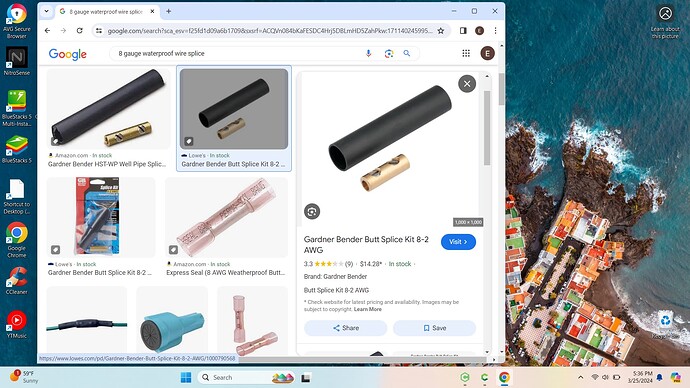

The type of connectors I had to use were #8-2 gauge screw type connectors with weatherproof shrink tube with sealer. The tube is slid down the wire, then the connector is attached with the wires going inside and the big heavy screw tightened to secure. then the tube is placed with the connector right in the middle and I had to use my gas torch to heat the tube down to size from center to end, then repeat on other side. The tube closes around the wire as sealer is pushed down all the way out the end of the tube. This sealer completely seals the wire throughout the tube.

Then when the wires are laid back flat, the dirt can be put back on top of it all to close up the trench. I wish I could have used just these smaller crimping connectors, but that wasn’t an option here. Each connector cost $15 each and I ended up needing 5 connectors. Then that one screwed up because it pulled out of the screw under tension and ruined the connection and seal. The last connector cost me $25 as well. I also bought weatherproof stretch tape for inside the tubes and some weatherproof sealant to help with what was available.

Here are those connectors I used.

As a total on cost for the connectors, tapes, sealers, and gas back and forth running around all over looking for the connectors, I spent a total of $250. It was worth it to get these wires fixed, connected, and sealed. I don’t want to have to dig this back up and do any of it again. Like I said before, I would have preferred to run a single line wire all the way thru to the breakers, but that would have cost me a few thousand dollars to do. Not in my budget at this time. Maybe in the future if the connectors I used prove to be faulty, which I hope isn’t the case.

Wow! The price of fun just keeps going up up up.

To make money one must spend money. I have spent a bunch on tooling for my machine as well. This wiring issue is just a step on fixing things correctly.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.