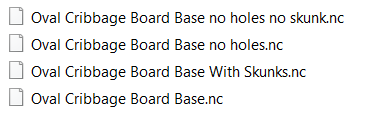

So I use the following format:

Name_bit type_Bitsize_options.file extension

For example a tool path named “Profile” using a 1/4" end mill would be:

Profile_EM_250.gcode

This assumes a datum of lower left… If it’s center then I would name it thus:

Profile_EM_250_CENTER.gcode

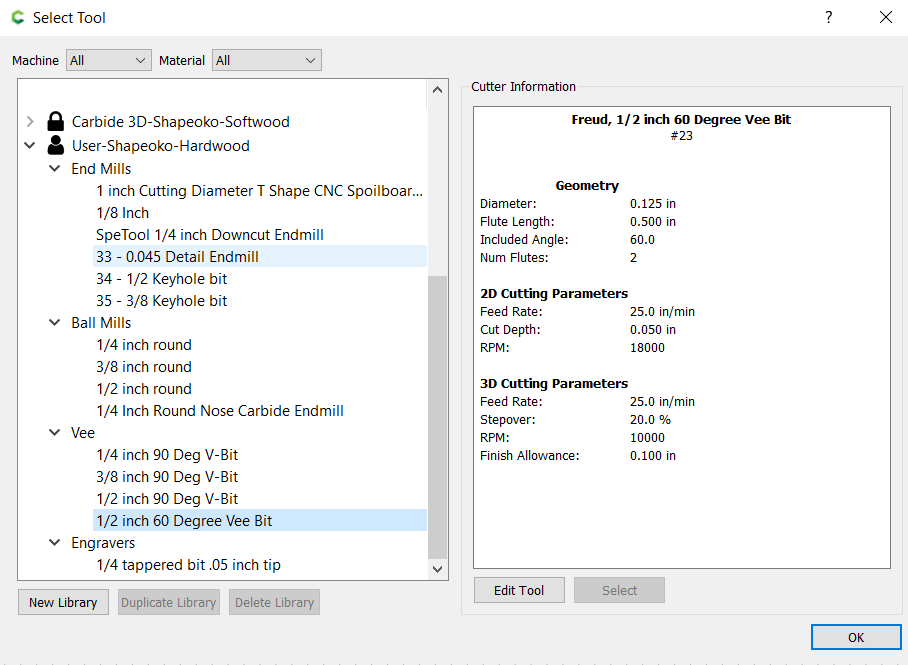

A 60’ VBit would be something like:

Lettering_VB_60.gcode or Lettering_VB_60_CENTER.gcode.

In some cases I will also include cut depth in case I have a few to accommodate different material thickness:

Profile_EM_250_0.25.gcode

Profile_EM_250_CENTER_0.27.gcode

This way, at a glance, I know exactly what I need in terms of bits, or a check to make sure I have the correct job for the bit loaded or material thickness.

Interested to hear how others name them…