Okay, working up a pocket cut which is:

- climb cutting (see: Climb vs conventional, definitive guidelines anyone? )

- ramps in (ditto)

We have the code:

rapid({x: px+plength/2-stepoffset/2, y: py+plength/2-stepoffset/2, z: 0}); // Go to start position

cut({x: px+pwidth-plength/2-stepoffset/2, y: py+plength/2-stepoffset/2, z: -dpp}); // Go to start position

arc(0, stepoffset, 0, -Math.PI, XY)//make turn

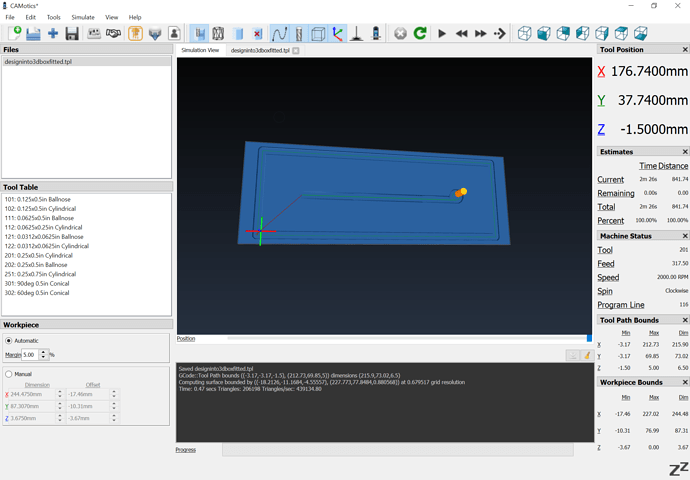

which gives us: