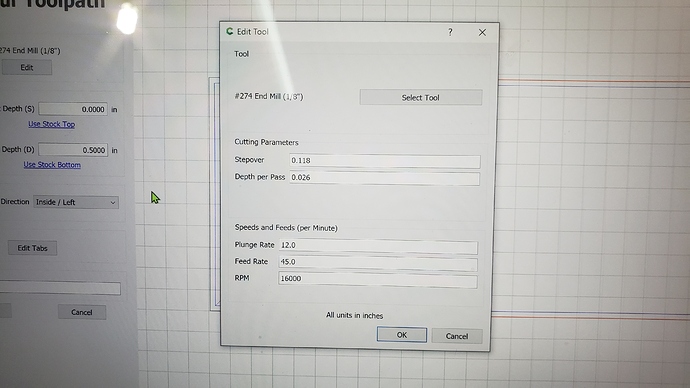

So I’ve been looking into speeds and feeds for cutting acrylic but when I try to apply my understanding to an actual cut I keep missing it somehwhere…

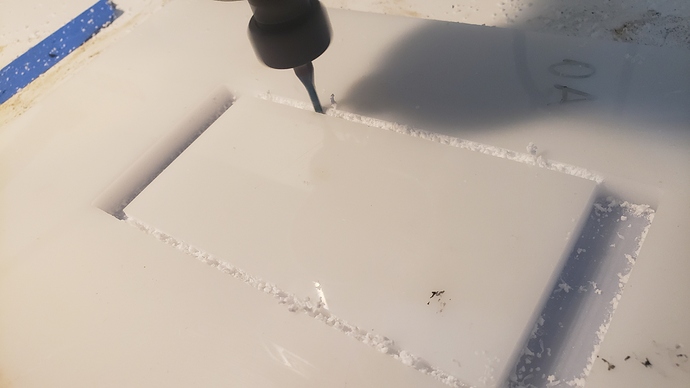

to start i’m cutting 1/2" acrylic where one of my cuts is supposed to be going all the way through to the bottom of the piece. I’ve been using the recommending setting with carbide create and the pocket portions seems to work ok but when I attempt to make my cuts all the way through I’m getting a lot of build up in the channel and the bit starts to struggle

I’m using an 1/8" downcut bit could that be the sole reason the channel is getting so clogged up? If so, would an upcut 1/8" endmill correct the issue?

Sorry if this may be a redundant question here but I am slow to learn some of this stuff and can’t rely on my own understanding of the topic…