I love my carbide3d probe but I had a few niggles with it.

First was tangled cords of the probe and the ground cable.

Second was not being able to unplug the probe from the controller.

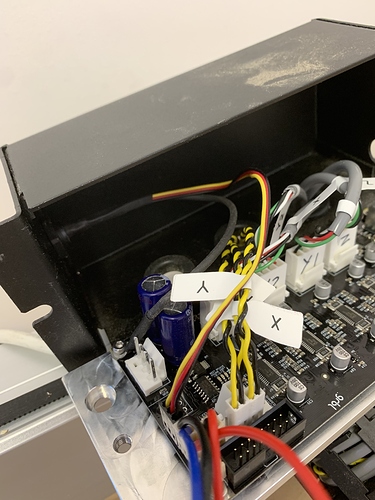

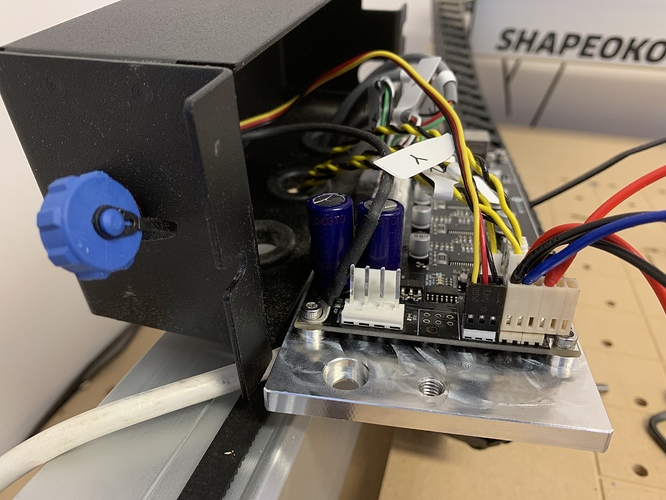

So today I made some changes. First was to install a 4 pin aviation plug and socket into the the housing of the shapeoko controller.

Second was to cut an old USB cable up as it is shielded 4 core cable that is fairly strong and wired that from the aviation plug to the touch probe. The touch probe only uses 3 wires so I soldered them to 3 points in the touch probe, The 4th wire is for the alligator clip ground lead. I then drilled a 3mm hole in the back of the touch probe and put the alligator clip ground wire for the probe through and shortened it to about 300mm long. Then I soldered it to the 4th wire in the USB cable.

So far I’m super happy with it. The single wire to the probe is way better and the ability to remove the probe cable from the controller makes cleanup time with the vacuum a little bit easier.