@Randy, I love you cabling. Could I ask you where you got the stuff to make it?.

Love it! Really nicely done!

All CNC machines need at least one handle!

I have rigid LED light bars in stock - the one I usually use for large CNC enclosures - so when my Nomad arrives (it ships today!) I will be experimenting with the best mounting. I have 6 and 12 inch ones so I’m sure I can come up with something I like.

mark

Awesome. Thank you. Looking forward to it.

@patofoto, I’ll report back in a day or two. I might have shot myself in the foot with the rewiring and need to run some tests. Spindle is intermittently cutting out for a second or two during runs, and that didn’t happen before.

Randy

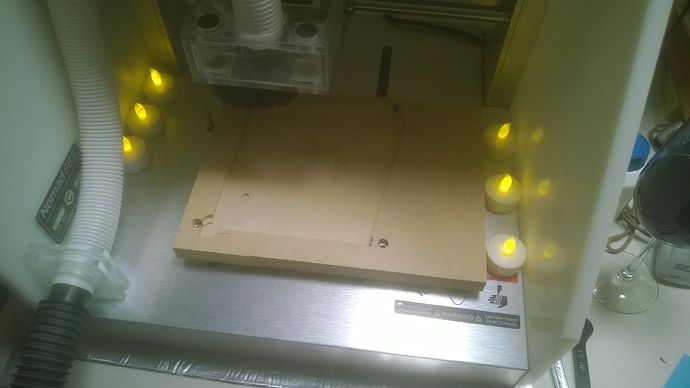

@flatballer, you have a good son.  I see the wine glass next to your machine. You should not drink wine while operating a CNC (unless it is a nice old-vine Zin…)

I see the wine glass next to your machine. You should not drink wine while operating a CNC (unless it is a nice old-vine Zin…)

Randy

That was in my hand when I was summoned to my machine by the youngster. I was an Elk Cove Pinot.

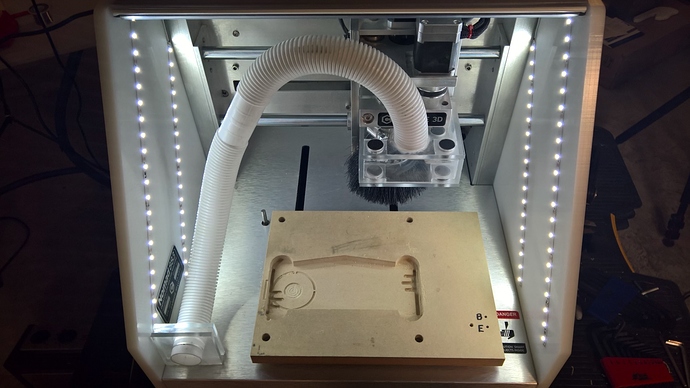

Here is my Nomad 883 Pro, now decked out with LED bars and the replacement bed.

The LED bars are Lightkiwi D5256 12 inch triangular LED bars in Cool White. They are sealed units - no dust can get in and they are easy to clean. I use them and their cousins from Lightkiwi for illuminating large CNC enclosures. I had them on hand so it made sense to adapt them to the Nomad. They are a 24VDC system, only 4W per 12 inch bar.

The LED bars are recessed such that they are not touched by the Acrylic door. The side panels can be removed normally.

I installed a switch/dimmer on the side.

Here is things at medium intensity:

I’m taking a break before cleaning up the wiring in the back right.

mark

Is beer acceptable Randy?

Anyone know how much power there is to spare on the shapeoko 3 power supply (24V 5A) for powering some LEDs?

I have about 15W worth of LED strips I’d like to put on the roof of my enclosure.

Is beer acceptable Randy?

Yes, quite, thank you. I can PM you my mailing address. ![]() (just kidding)

(just kidding)

Randy

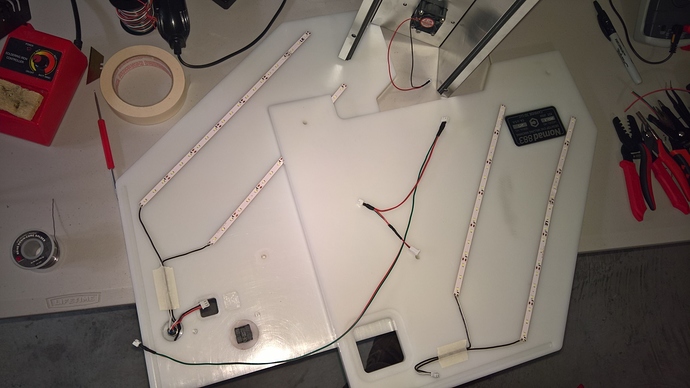

Just did some minor surgery replacing a faulty Z motor, and I went ahead and built in some lights with a simple harness that pigtails off the 12V fan jumper, no issues so far.

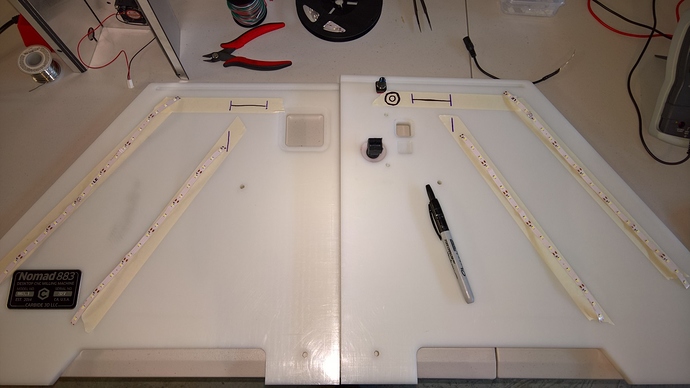

Laying out the lights, wires, and switch:

Lights installed and new harness to connect them and the fan:

Installed:

WOOHOO! VERY NICE!

mark

P.S.

I HAVE to ask. B? E?

Ball Mill and End Mill holder holes, being lazy making lots of 7"x7" litho frames.

nice, off the 12v fan jumper aye, will have to do the same

Yes, and I used some JST plugs to make the harness so that it can be easily disassembled when the need arises.

So after a bit of use I have found that the LEDs do slightly flicker when running the spindle at 10000 rpm and moving in all 3 axes at once. No flicker at all when doing job setup. or lower power motor activities. So not leaving them on all the time is my current solution. Also its almost too bright.

This is why I just went external 12vdc power pack. Amazon has some slick ones with nice long cords.

-Hank

Didn’t want to have to worry another power supply. If worst comes I’ll make a simple board to pull off the 24v supply.