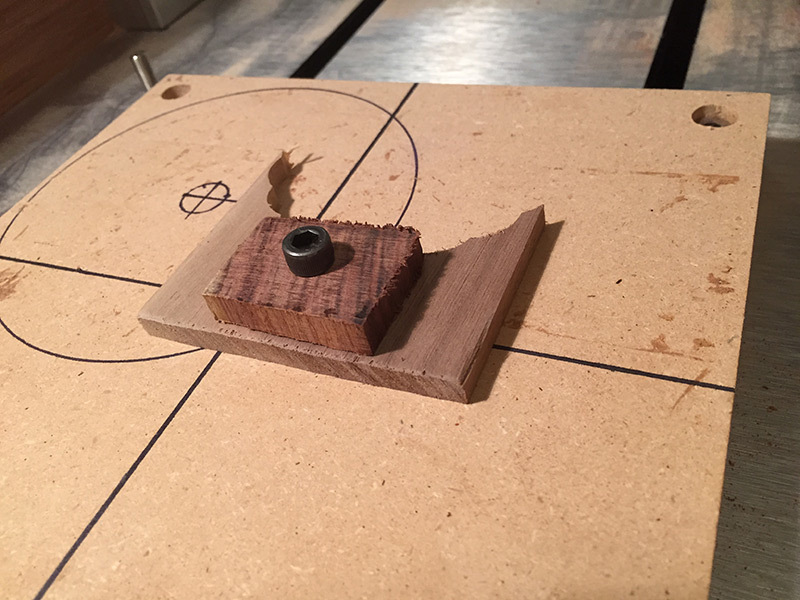

Well, so that all worked… sort of. Progress, anyway!

Now I just need to up my flip-jig game. I had thought that bolting stock directly to the table would be fairly precise, but I did notice a lot more play in the position than I expected. It’s partly because the mounting hole I drilled in the stock is imprecise, but even just experimentally the bolt (even under some tension) has a bit of play in it.

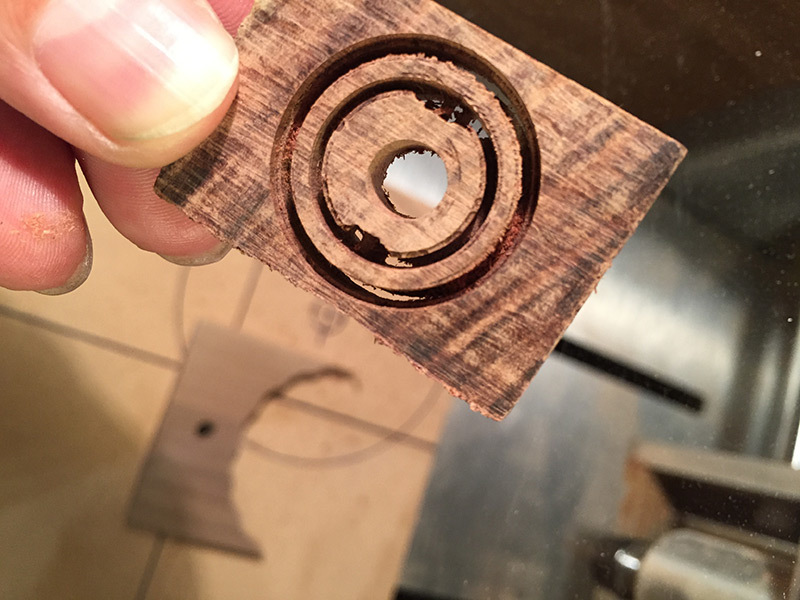

So here’s how things turned out. A few notes:

- Using Randy’s exclude area trick instead of modeling the center column works fine.

- dr_g is right, and my supports were not aligned very well. But there were bigger alignment problems.

- I’m using an end mill, when this really calls for a ball-end.

- The Nomad auto settings for hardwood are a little aggressive for this smaller 1mm end-mill, but when I adjust things it does a very good job on this ironwood.