I’ve had my pro now up and running for about a month and I’m cutting often…really enjoying it! I’ve already made around $1,800 with just one basic product. Anyway…I’m new to the CNC world and to SVG’s and the learning curve has been steep but rewarding. Why do some SVGs cut really well with a V-bit and others are a disaster? I’m sure it’s a tool path issue, but I don’t know quite how to approach fixing it. I have a US Army logo I’d like to v carve, but it just will not cooperate. The US Marine Corps logo have works perfect. Any insights would be helpful!

Sometimes, an SVG looks fine at first glance but if you zoom in enough, you see that the edges are actually not smooth at all and there are tons of tiny segments that can mess up the quality of the toolpath (and therefore the cut). Maybe check that first? It’s a common issue with SVGs sold on e.g. Etsy, by folks who use bitmap tracing converters to generate the vectors they sell, and did not bother cleaning up the small details.

It can be many other things obviously. If you can share the vector that does not cut well, we can have a look.

If you have a file which does not cut well, either post it here, or send it in to support@carbide3d.com

btw there is a trick… you can re-trace the SVG. Basically what I do is import the SVG into gimp at an insane high resolution (like 300DPI, so 10240xsomething or so) and then import that into inkscape to re-trace the bitmap into a vector. that way I control the smoothing parameters etc/etc and this has allowed me to “fix” several problematic SVGs so far.

Here is the logo I’ve been working with.

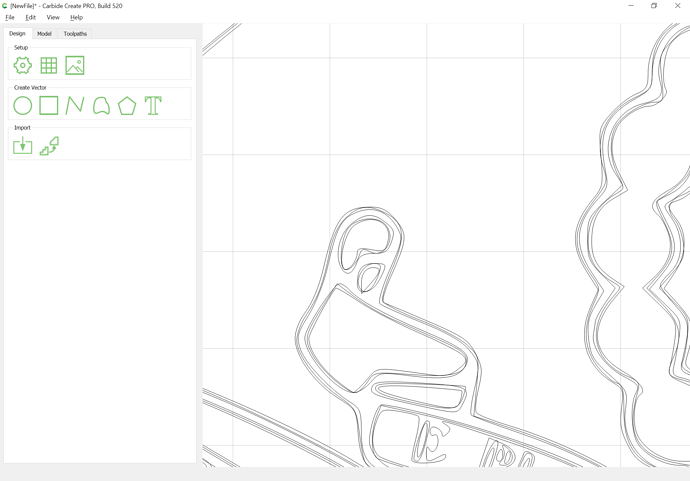

The problem is this image is a tracing with multiple paths for each element of the design:

Why not get a vector original?

This is available on Wikimedia:

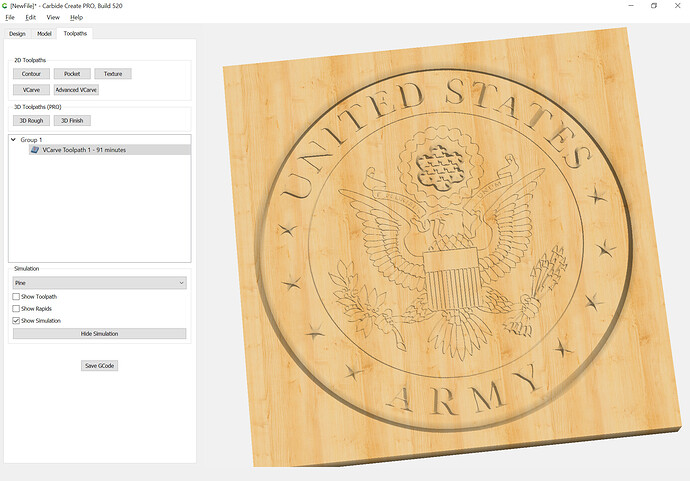

Hang on, we’ll make a version suitable for cutting.

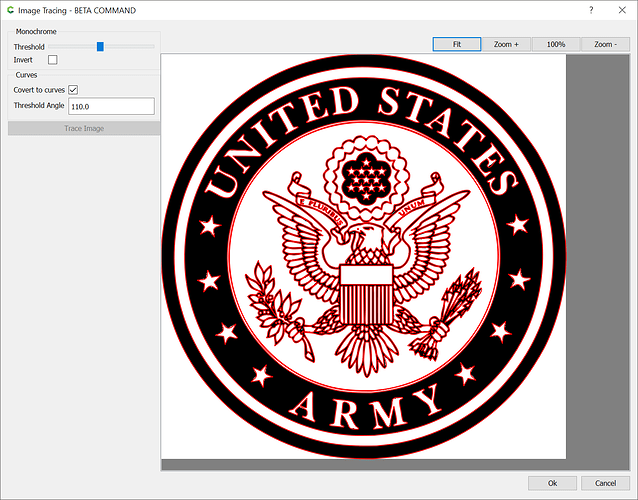

It does make a challenging example for the new auto-trace option:

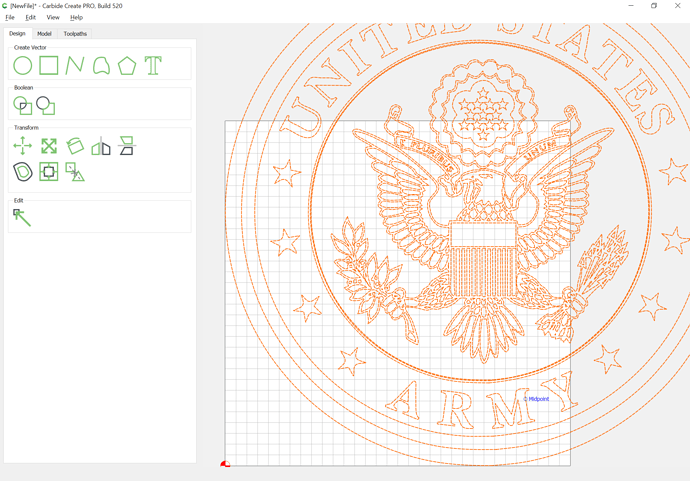

A little cleanup and we arrive at:

Attached.

usarmy_autotrace.c2d (1.4 MB)

This is the stuff I need to learn to do! You are awesome…thank you!!!

David and Will - Thank you. Just reading this thread solved one of my issues. Also new to CNC. Just got my Pro XXL (black friday special) and already produced multiple things. Like many, I’ve made a lot of flags in my time and now love doing them on the Shapeoko now. I use an advanced VCarve path for my stars with a 1/8 end mill for the pocket and a 90 degree Vee for the VCarve. I love the look of the stars with the 90 degree better than the 60. For the detail on the USMC eagle anchor Globe or the US Army file, as you’ve shown, a 60 degree Vee for the VCarve path works better than a 90. This helped me, so thanks.