Question when is it a right time to use the 1/4 and the 1/8?

For me, I use the .250 to do a profile cut “outside shape”, I use the .125 and 60 vee for everything else.

The .250 makes a better cut through the material in my book

In the most general sense, think of an endmill like a paintbrush. You usually want to use the biggest one you can get away with to save time. Detail work will require a smaller tool. The main reason I would use an 1/8" even if a 1/4" endmill would fit is if I’m cutting something more delicate. The 1/4" tools bring a little more violence to the process.

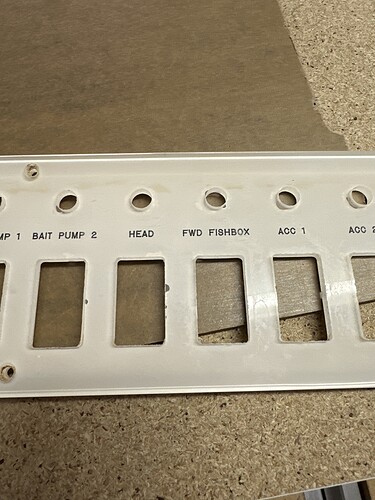

For this panel, for example would it be better to use the 1/4? I’m running it through by carbide create with the 1/8 but it says it’s going to take around 45 minutes. For the contour for the outside, is it also better to use the 1/4

Looking closely at your image, I don’t see a nice clean edge to your cuts. Is your cutter damaged? Look at the edges on my acrylic cuts and see if they look different to yours. Make the image as large as you can… there is a size increse button if you mouse over the image when viewing it in the forum. A close look at the cut marked FWD Fishbox will illustrate the appearance to which I am referring.

The white panel is someone else’s. I’m just using it for a reference and copying it so I can get the measurements right. But for the rectangles, I wanted to know if I should use 1/8 or the 1/4.

The 1/4 will hog out more material quicker but will not get the corners as tight as an 1/8 bit.

If you were only doing one rectangle it would probably be better to use the 1/8 for the whole thing to avoid a tool change. But since you have so many it is probably worth a bit change so do the 1/4” to get most out and clean up with the 1/8.

If you don’t have rest machining, I think it’s in Pro only, then you and draw a 1/8 inside offset from each rectangle and select that vector and the outer one for the 1/8” toolpath.

It really depends on how sharp you need those corners to be.

The other thing to consider is that the settings in Carbide Create by default are pretty conservative. As you get comfortable with the process you will learn what you can get away with. In many cases, you will find there is significant opportunity to increase the settings with minimal risk. So think of those default numbers as worst case.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.