I keep the tops attached to the first ring to keep the lids intact and strengthened–helps retain the pieces from bowing/moving on reassembly.

That looks so good! I wish I had that option, but by the time I get the lids, they’re long separated from the ring. I’ve still not cut the lid I was going to test on. I took it apart and am gluing it together one piece at a time. I still don’t believe it’s going to be flat enough though ![]()

Perhaps this is better suited for a laser engraver.

Unless they really want a rough look, you could surface (plane) both sides to get a consistent, flat surface. If you are going to stain the finished product, then I doubt anyone will notice that it was planed smooth and flat before it was carved.

If you are using a test piece anyway, then carve the test piece as it is. If it doesn’t come out as expected, then plane it out (if possible) and try again with your new, flat surface. Let the client decide if that look is acceptable.

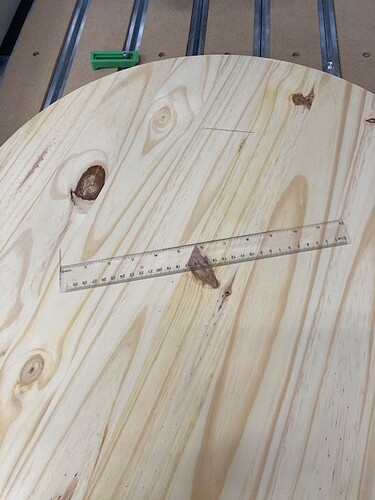

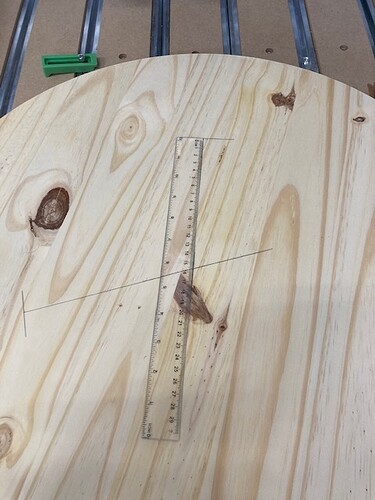

This is the easiest way I have found to find center. Draw two cords and find the center point. I did 20" for easy math. Off of those center points measure perfect 90 degree angles and extend the lines toward the center. Where they intersect is the middle.

Thanks for all the advice folks!

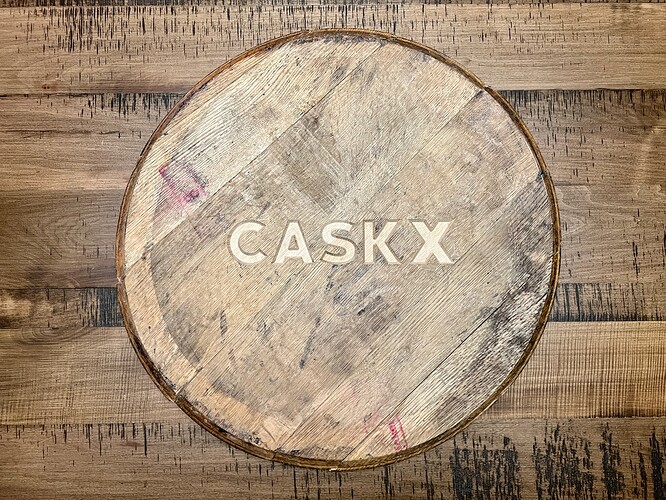

Gluing each part separately helped keep the lid as flat as possible. I’m fairly pleased with the cut!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.