I made what I’m calling a “wax chuck” awhile ago. It’s pretty neat, adding a workpiece is as simple as heating the work, setting on the chuck, and letting it cool.

That said, it’s a pain to re-zero to the center of the work piece every time. There’s no centering mechanism:

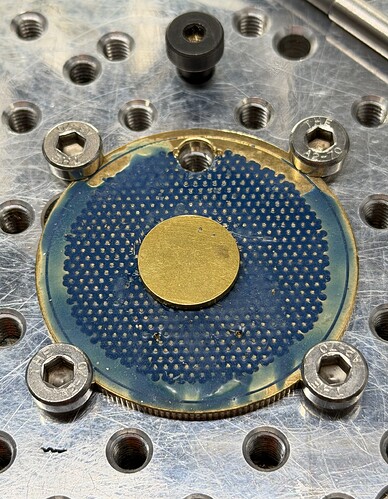

(Perfectly centered workpiece ![]() )

)

And that’s what we’re fixing in this thread! Hopefully! (I’ll change the title to “WAX Fixturing Fun” when it’s done ![]() )

)

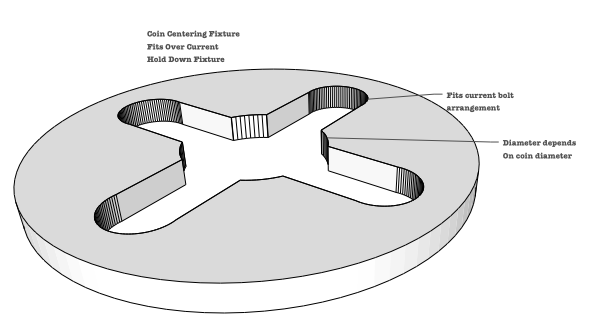

Here’s the plan:

The orange piece is a shim that is a half mm thicker than the chuck, this puts the v locating fixture above the wax but still low enough to hit the sides of any work piece.

The green sits on top of the orange shim. This locating fixture slides while being constrained by locating pins in a precision slot (the black bolt has a precision turned shoulder to allow lightly clamping the fixture while still constrained)

The hole in the chuck will have a smw locating pin, it’s not pictured here.

So far, this allows locating things like coins on the Y axis. I use the same few diameters most of the time, so I’d like to index the sliding fixture to put the centers of those diameters in the center of the chuck…how hard could it be.

Not sure on how to do this yet but I’ve got some ideas:

-

Magnets: They make everything better but I’m not sure how repeatable two aligning magnets are.

-

Ball detents: most likely scenario, easy enough to do accurately and adding more detents is easy.

-

Shim side grooves: another detent method just using ridges on the shim sidewall. Seems unnecessarily complex.

I’m drawing things up now but feel free to share feedback and ideas ![]()