Ok. This time the same .nc file, same type of wood, and same xyz 0 point and it came out fine without any issues.

That means the issue must lay with the machine. Any idea what can cause that?

I can’t prove anything, especially since it only happened three times, but I initially had the exact same problems and once I slowed down (slower than the auto-toolpath settings) the problem has not returned.

Yes it takes longer, but I’m more comfortable with the slower settings too the point that I don’t feel the need to stay in the room while it is working.

It might be worth trying clear-grained wood, Oliver. Knots can be really hard, and I’ve ran across knots that even slowed down a trim router. If the knot stalls the spindle (or even slows it down so that it isn’t really cutting) I can see where the axis drive could miss steps as it tried to drag the cutter laterally. Since the steppers are driven open-loop, the Nomad has no idea that anything has gone wrong. When a stepper motor is overtorqued, it doesn’t just slip a little–it stalls until the next commanded move. Steppers need to be ramped up to speed, so they can’t pick up in the middle of an existing move.

Randy

Hi Randy,

good idea, and i thought that was the issue with some other wood i used before, but this wood doesn’t have any knots at all. Plus being off for more than 2 inches is a lot i think. Its pretty hard and fine grained (Jatoba Wood).

It must be something else, since the same carving from the same wood (which came from the same board) worked without issues. Plus being off almost exactly half of the width of X makes it a little bit too exact to be a slip up, seems more like a miscalculation somewhere or so. Not sure though of course

Hi Oliver,

The distance that it’s off by (approximately half) doesn’t rule out a slipped stepper—one option would be that it crashed about halfway through a rapid or linear traverse, so when it picked back up the X-axis was off a lot.

Also, remember, once it’s slipped it stays misaligned/disoriented until it has been homed again, and these errors accumulate. If you’ve seen it getting progressively worse then you probably have some lead-ins or transitions from a plunge to a traverse where it’s momentarily overloading the tool and losing traction.

If that’s the case then fixing it would just require adjusting the acceleration profile for the machine for the material, and/or setting a less aggressive feed speed.

I compared the Janka hardness of the Jatoba to other hardwoods that they’re likely to have set the automatic settings for—I’m guessing woods like white oak—and it’s rated at 2350psi whereas white oak is 1350psi, so per this write-up about guesstimating feed/speeds for woods, I’m betting your asking your Nomad to bite off more than it can chew.

Hi,

thanks, yeah i will try to change the automatic setting then and see if that solves it. But i would think if thats it, it would come back every time i cut the wood and not just sometimes. Plus i had that issue with Douglas fir before, which is really soft (i think)

Hi,

I have seen on my 3d printers, that the steppers can miss steps when ran on to high speed. Check the themperature of your steppers and stepper drivers.

Johan

Hi,

and it happened again, this time with Renshape (using the Meshcam Renshape tutorial) and a very short .nc file.

It started all of a sudden drilling about 2mm off the spot where it should be (see attached pictures, especially the round holes on the left). the workpiece definitely didn’t move this time (in fact i have a hard time right now removing it).

It happened last night again too at a longer carving after about 6h, when the parallel run started. It was off by almost exactly 10 mm, and again on the X axis…

I really think something is up with my machine, maybe the board inside the Nomad is hanging and skipping some steps, or the belt jumps or so, i am not sure but this example above was really a very easy to drill piece, that didn’t take much time so the machine didn’t run for a long time, and I used renshape so it cannot be the hardness of the material or knots inside, and it was just some basic hole drilling involved.

Please advise!

Thanks

To me it looks like you have been much deeper into the stock, than the lenght of the cutting area of your drillbit…

Johan

Hi Oliver,

I think we’ve found at least part of the problem—you’re using a tool that has a tapered shank, and making cuts that are deeper than the cutting length of the flutes, as Nahoj noticed. What’s likely happening is that you’re running the shoulder of the tool into the material, which of course isn’t cutting… so something’s got to move—in this case it’s the steppers skipping steps!

If you can go back through your setup and your tool selections where you’ve had issues, can you identify that you’ve been driving the tool deeper than the flute-length in the material along straight walls in each case? For deeper cavities you’ve got to get long-reach tooling, or you have to taper the walls so you won’t hit them with the tool.

Let me know if you can confirm the total depth of cut and wall angle as the issue or not

Hi,

good point, at least for the item in renshape, not for the longer piece that failed last night. That piece did not have a frame at all where the tool could hit (its a landscape relief). No straight walls on that one, it started right at the point when the finish pass started.

so 50% of the case is resolved

I also wanted to add that i use the very same wood (Jatoba) for other carvings with the exact same settings in Meshcam and final cutting depth and it works well. The only difference is that the one that doesn’t have problems is only about 3h long while the problematic one is a 8+ hour job.

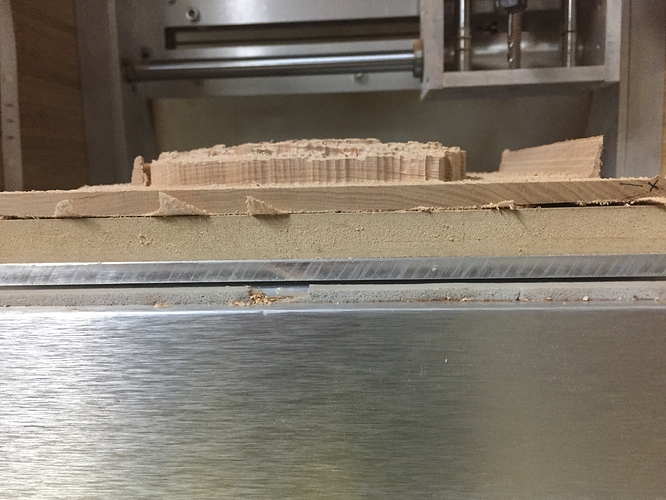

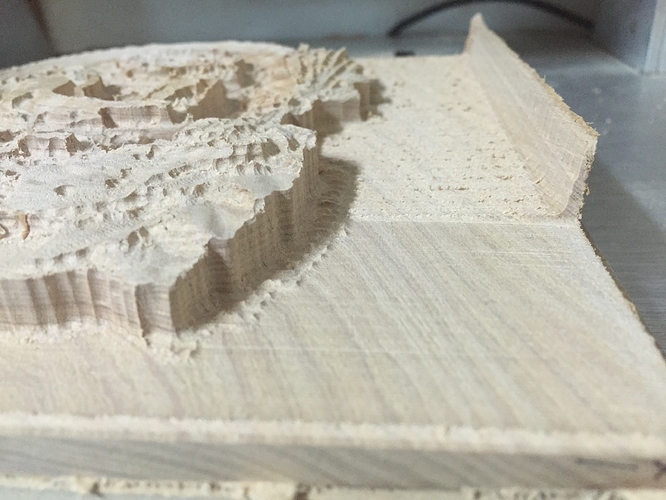

This thread is kinda stale now, but i want to bump this again since it happened again. And this time you can see it nicely, it was all fine until the ‘Cut X then Y’ started. You see the smooth part (where it started cutting off the part on the right side). I used a 101 cutter.

Can you post your .stl and your MeshCAM tool-path settings? That’d make it easier for the rest of us to have a look.

My guess is that your stock definition didn’t take into account the ridge you’ve got over on the right edge, so it looks to me like the cutter stalled while going rightward, into that ridge.

It also looks like that ridge is uneven, and perhaps even deflected a bit, can we get a “Front-view” of the stock in addition to the “iso” you’ve provided?

Hi, I can try to send the .nc file once im back home. I used #101, with the default 101 setting in Meshcam. The only thing change i made was disabling the setting for Angle Limit 50 degree (or what it is called), so that the NOMAD actually smoothes it later, otherwise it stays with the ridges.The stock was a flat piece of wood, it cut it fine just once it went into the finishing XY it started being off. Anytime that the NOMAD is off (and i had it several times now, especially for longer carvings), its in the finishing pass at the end, which is nice to see since it was off at the point when it started on its x finishing pass. It almost looks like that stepping artifact because that ridge is also not straight but shaped like a wedge. Jorge wanted to send me a new board once the shippment gets in to them too.

As in my reply to the other post, seeing your meshCAM settings will also be helpful, but I’m also thinking there could be board shenanigans contributing.

It looks like your wood may have cupped a bit during cutting? That could also cause the initial engagement of the tool to snag, and per my comment above, if it’s hitting a full tool-engagement on what it’s expecting to be a finish pass, that could cause it to bog down.

Hi,

i will try to get the settings later, but i always use defaults and just uncheck the Angle limit check-box to get it smoothed.

Rest is default. The cutter is the correct one, i have checked them all after getting a few mislabeled ones, so i can rule that out too

The bending off the wood is caused by me trying to get it off the plate once i stopped the job, but then decided to leave it on there for the pictures.

Same thing again, a longer carving, but not very deep.

Also, its fairly easy to see on this one that the X axis is wandering off towards the longer the job runs.

.

It looks like a double-vision on the bottom of the circles if you look closely.

Also, there was a ridge on one side of the carving that was getting wider towards the bottom, although it should have been a straight wall (like in my first post above). The cut is not deeper at any point than the flute itself, or flute + neck so the tool never should have hit any sidewall.

@Jorge : do you think the new board will fix that issue?

Dooing the recommended modification, fixed the same issue on my machine.

Changing the board fixed it for me too. I just finished carving the same piece from the same file and same wood, and no issues this time, very happy