I want you to excuse me, but I have already used a base in engineering plastic, in wood and come to the coclusion that the base must be rigid, either in aluminum or iron.

I have already used a base in engineering plastic, in wood and come to the coclusion that the base must be rigid, either in aluminum or iron.

I take your point JoseD3. However cost is a consideration for many.

Thinking about it though, already there are a lot of plastics in a Shapeoko in the form of V-wheels and Belts all significant components!

Yes, but there’s also “The Wonderful One-Hoss Shay” aspect of it, and the thing only being as strong as its weakest link. That should be the V-wheels — any wear / distortion should happen there (and they’re relatively inexpensive and easily replaced).

For some folks, cutting some materials, the MDF won’t be workable, but for many folks, it’s fine — it’s a kit, and the wasteboard is one of the most customizable aspects of it.

In my case I cut hard wood, copper, aluminum and require exact measurements, but my council is the fruit of working every day with Shapeoko, I also believe that the person who has one of these machines at some point needs to make a accurate cut . You can put now or leave to do it later.]

I just received an email from Carbide they now have a T-Track table, just ordered it for my xxl.

Can’t wait

Nice, How did you fasten the MDF to plywood

Just used 6-8 timber screws per length of mdf, and countersunk them so they sit 1/4” below the surface

How is the board keeping up, any sag or is it staying true?

Has anyone thought to use signboard? Its aluminum sheet, with corrugated plastic in the center (although you can buy some with solid ABS in the middle too)

Its fairly rigid, light, and a 4x8’ sheet from a signage supplier should be about $80 or less, and you can cut it with a good condition circular saw.

No sag at all, I have surfaced the sacrificial MDF board twice, due to me cutting into it during jobs, but no visible sag

I would like to do a threaded aluminium wasteboard, but can’t justify the price until I find some cheaper aluminium plate

The signboard does sound good value but I think generally the heavier the better for wasteboard, I will call my local sign maker and see what they’ve got though, even if it’s for a project rather than the base board

It would make a good base for the wasteboard, to help with sag, and be great for enclosure walls.

I might run a steel base first and then aluminum on top when I start to machine aluminum with the router. I regularly get stainless laser cut, a 10ga sheet shouldn’t be too bad on the pocket book to add to one of my orders. Hell, They laser aluminum all the time, I should inquire about that. Hmmm.

If pouring resin do NOT pour more than about 8mm in one thickness or you will run in to troubles as it cures…it generates heat. Better to pour in multiples of say 5mm up to the thickness you want and leave to harden for a couple of days and then pour another layer.

Layers bond fine

Great, What did you use or how did you fasten the 1 in ply to cross rails, original fasteners or store bought?

I used store bought stainless bolts, they were part of an assorted pack, approx 1 1/4" long. I just lay the original base board on top of the ply and transferred the hole locations, then Counterbored them so I could mount the MDF strips flush. From memory the base board bolts were too long and hit the table my router sits on, so I had to cut a bit off them.

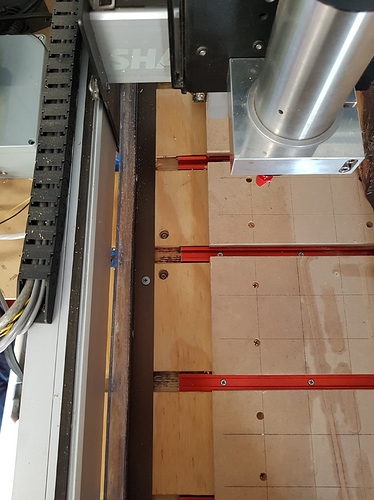

As you can see I also (hand) routed slots for my t-slot and screwed it in too.

My experience with bamboo plywood:

Tool wear is much higher than other plywoods, glue and physical characteristics of bamboo might play a part?

Very stable, just let it acclimate for a week before using

Very mechanically stiff compared to MDF

Price is orders of magnitude higher than MDF

I think down-cutting bits/cutters should be used if cutting parts out of it…

Good luck!

I much prefer the threaded wasteboard.

Fair call, I was using a threaded MDF wasteboard for some time, just like the one you’ve done in that link you posted. It worked quite well but I find the T-slot gives me a bit more flexibility, I have had a lot less issue clamping odd-shaped pieces of timber since I made the change.

It all depends on the work you’re doing I suppose.

i fixed that by making different sized cam clamps:

It can be helpful to have a right angle “L” shape corner with at least 3 holes in the X and in the Y.

And a basic rail with 4 holes.