Greetings.

I received help from the forum with homing errors last week and here I am again!

I haven’t talked to support but will depending on the results I get from the community.

I’ve tried a simple project, a hexagon with text (Ted) inside outline with a pocket. The first couple times I tried to cut it in plywood and it started out well but then seemed to lose track of where it was working and carving over the letters and outside the pocket area it had been working in. I moved to some MDF and tightened my Y axis belts a bit and tried again. Same error. Did some research and saw mention of making sure the pulleys were tight on the servos. I checked them out and while I could tighten them up they certainly weren’t loose. Another run while I sat and watched through about 40 minutes when the letters started to break off thiner pieces. I was trying to cut the pockets to a depth of 0.3 inch so I backed off to 0.225 and tried again. I wandered off a bit and came back to another case of the Y axis looking skewed.

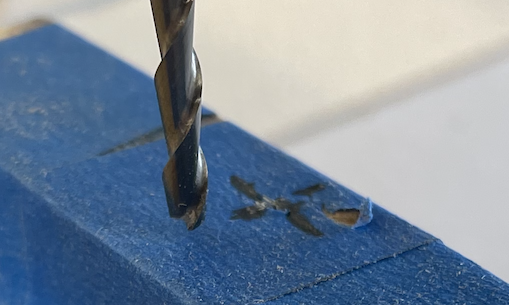

I paused the run, recorded the X, Y and Z positions and setup a stack of a couple pieces of wood, with tape and a mark for where the bit was at those settings. Stopping the job causes the spindle to initialize back to SW limits. I then returned it to the X Y and Z that I recorded and took the attached picture, where you can see that the Y is off from the setting in the previous job which would account for the errors in the carvings I’ve been seeing.

I have my belts very tight and the pulleys cranked down about as far as I dare.

Suggestions appreciated.

Ted