I’ve seen posts of people’s cutters diving too deep but mine is doing the opposite. One the second tool path the cutter will begin its path about a half inch above the material. Just cutting away in midair even though the first tool path seemed fine. I can stop the program, send the cutter to zero + 6mm and all seems fine. Restart and same issue. It doesn’t always happen though.

Specs, scenarios and pics below.

Brand new XL with Z-plus and BitSetter

Latest versions of CC and CM

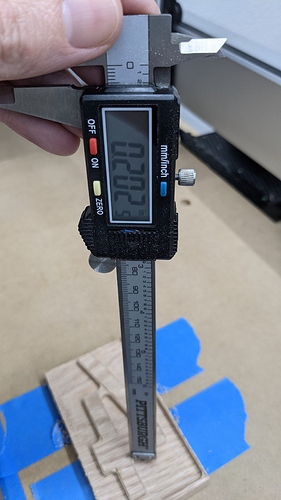

I zero the machine manually using a piece of paper to set Z.

Occurrence 1, first tool path started properly but never went through the material as expected. It stopped about .25 inch too shallow. Second tool path began and was routing above the work piece in midair. I stopped and zeroed and all looked fine. I modified the CC file to remove the first tool path and loaded in CM. Double checked zero, ran it again which would only run the second tool path and saw the same issue, cutting in midair. There was no tool change in this job.

Occurrence 2, VCarve inlay using advanced vcarve tool path. The cavity job ran great without issue (walnut image). The inverse seemed to run the bulk removal part just fine. Tool change to vbit and again it started cutting in midair. I let the job fully complete and checked zero and it looked just fine. Cutter was 6mm above the surface as expected. This job had a tool change since it’s an advanced vcarve but it was all one tool path.

Thankfully both of these were test runs so nothing was ruined. Any ideas? It’s not the end mill slipping up into the collet. I’ve triple checked all depths and material thickness in CC. The material is not moving around. The material is thin so I am not maxing out the Z on path/tool changes.

Thanks!