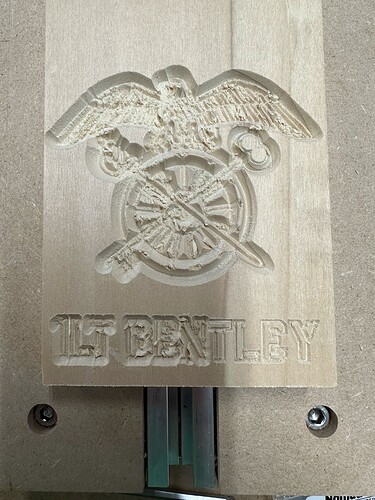

I can’t figure this one out. I started a vcarve toolpath after manually setting all axis zeros. I’ve uploaded a picture of the results. A few of the letters in the vcarve (“TLEY”) came out fine. But then the bit really started digging in and hogged out the rest of the letters and the logo. I checked the z zero after the job by jogging to it and it was noticeably lower. I also had a job yesterday where the machine perfectly cut two pockets but then started a contour and in the course of about 8 inches of travel plunged through 1" of hard maple and snapped the blade.

Any ideas?

Usually difficulties such as this are caused by a disconnect in how the origin is set in the file, and how zero is set relative to the stock — if you have difficulties with a correct setup and matching file, let us know at support@carbide3d.com

If you are digging in deeper over time, some culprits may be:

- Bit slipping down in collet.

- Wiring issues causing missed steps when raising the Z axis

- Too high retract height, so missed steps at top of travel.

I appreciate the comments above but support found the real answer:

I have the HDZ and there are two set screws for the coupling between the motor and ball screw. Those screws had come loose a quarter turn and that allowed slips and jumps. I’ve tightened them up and so far the problem hasn’t returned.

Thanks Eugene in Support!

7 Likes

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.