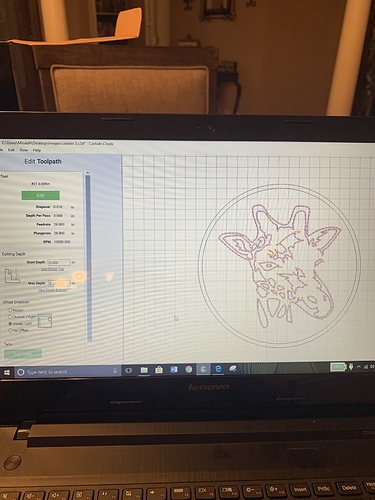

I am trying my first project and I am having an issue with the z plunging into the board all the way even though I’ve asked it to only go .15 inches deep. I am using a 1mm bit that i set up in the library. Any idea why it’s doing this?

any chance you could attach the .nc file?

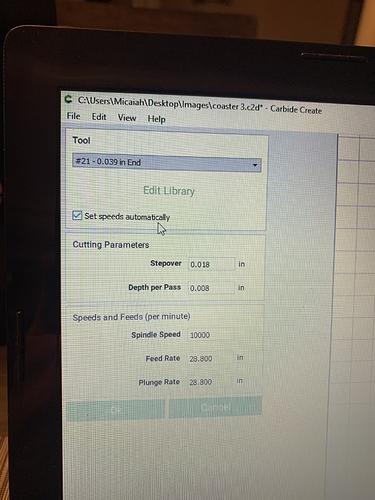

also a plunge rate of 28 and feed rate of 28 for such a small bit is not great, I’d go with a plunge of 8 and a feed of 10 at most…

This may be caused by a number of different things:

- a disconnect in how the origin is set in the file and how the zero is set relative to the stock, see: https://docs.carbide3d.com/tutorials/tutorial-homing/

- if using the Probe this may be caused by setting the Probe as for an X/Y/Z probe at a corner, but probing for Z only, see: https://docs.carbide3d.com/assembly/touch-probe/userguide/#probing-xyz (the Probe should be fully on the surface, rather than only the body on the stock and the 3mm lip off the stock)

- setting the Z-axis safety/retract height in the CAM program (Job Setup | Machine | Retract Height in Carbide Create) to a value greater than is available above where the machine expects the top of the stock to be, resulting in the machine bottoming out against the top stock, thinking it is too high, then plunging down too far in an effort to travel down as far as that failed effort would allow. Setting the origin to the bottom of the stock/wasteboard surface, while setting the zero to the top of the stock may also cause this problem

- a mechanical difficulty — check pulley set screws, Z-axis belt tension

- an electronics issue — check the wiring and connectors

Where is the .nc file located? Apologies but I’m really new to this

I tried to probe it on the corner with x,y and z. I also set it on top and probed z only. I also tried to manually set z on top of wood and zero there. Everything causes it to go through the board. I just tried my first project with no issues so I don’t think it’s mechanical or electrical.

Please post the .c2d file, generated G-Code, and step-by-step instructions on how you are securing your stock and setting zero relative to it in CM here or to support@carbide3d.com

it’s the gcode file that you loaded into carbide motion

I secured the stock with the clamps that came with my T track. I tried to set zero three different ways. I used the touch probe on the corner with the overhang off the wood. I set zero for all three at this point. That did not work so I put the touch probe on top of the wood and set zero only. I also tried to manually zero without the touch probe by setting the bit to the wood and calling that zero. All of them gave me the same results. The bit goes down just above the table mdf and starts cutting the pattern. I bought a pack of small end mill bits and set them up in my library so I could make smaller cuts. I used the 1mm bit and set it up in my library with a 5mm flute length. My goal was to make a 1mm cut around the drawing. I would use a 1.5mm to pocket the drawing. I am adding the CC file and the g code file. My last cut, and my first, was a sign and I used a V bit and V carve. It worked fine.coaster 3.c2d (343.3 KB) giraffe g code.nc (3.0 MB)

you have your retract height set WAAAAY too high (3 inches!)

this causes the Z to hit the top of range and then some. the “and then some” gets cut off, and then it goes down 3" again

easy to fix, in CC go to the “sprocket” menu, and set the retract height to 0.3 or 0.08" or so

Thanks. I will change it and run it.

That fixed it. Thanks again for the help.

btw when wondering if your gcode file is sane or not, https://ncviewer.com/ is a great website to see what it will do…

Glad you found the issue and here is another way that this happened to me. I use Vcarve and it allows you to set the origin at the table level or the top of the material. When it is set at table level but I zero to the top of material the cutter does not reach the wood to cut. If I do the opposite it would cut through all the material and down into the table.

Whenever the machine chatters while finding a spot that is a sign it just lost its zero setting. I am sure you heard that chatter when this happened to you.

regards,

jg

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.