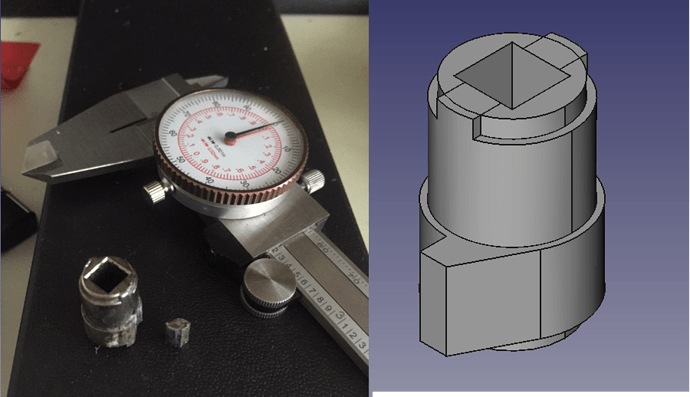

An interesting small part challenge this weekend. A powdered metal pawl inside a fingerprint door lock let go after some serious abuse. No replacements parts available. Some quality time with some callipers and FreeCAD to model and it was prototyped up as a two sided job in HDPE on the Nomad. 0.125 end mill for roughing and finishing followed by a pass of the 0.031 end mill on the ends to get into the corners. Needle file to square up the corners of the square hole. A test fit of the prototype worked so well it is going to stay inside the lock until the brass stock arrives to mill a more permanent solution. Money (and hassle) for a replacement lock saved! (and then quickly spent on more CNC toys) In the excitement forgot to take a picture of the finished part - only have the broken part and the CAD model as shown. Will add the brass part when done!

Very well done!

As a guy that has had to deal with his share of lock issues, I can say the average Joe often doesn’t understand what goes into lock replacement. When possible, servicing an existing unit can actually save a tremendous amount of time and money.

Thanks! Agreed, the surgery required to get into the lock without it exploding all over the place along with the fussiness of the parts alignment made just getting to the pawl a real challenge. As it turns out the locksmith who installed did not set the travel stops for the lever handle properly, thus transmitting all the force of abuse onto the tooth of the pawl.

The lock was one of the first fingerprint ones and cost a small fortune along with making a huge hole in the door. It was either fix it or replace both the door and the lock. Probably looking at half the cost of the Nomad by the time it was all done, so can one could say the Nomad is half way paid off, right?!?

Yep, those #'s do not surprise me at all and warrant another at-a-boy!

Look forward to seeing pics of the brass replacement. I hear brass machines beautifully, I look forward to your report.