I am attempting to V-carve a dog’s head into the backs of adirondack chairs. I had 2 double images. I did a do-over in Create, carved a perfect practice head, put the chair back down, lined it up and, ended up with a jumbled mess. I restarted the computer, made the image in Create from scratch, changed the name (thinking it may change the path) and started carving. It began carving, this time, about 4 inches off center and making cuts where there should not be cuts. I stopped the process. I had previously V-carved this dog head on 3 occasions with a couple of other images in between, with no incidents. If you are going to ask me to send you gcode, please explain in detail (step by step) how to accomplish this. I’ve tried before and do not understand how it’s done.

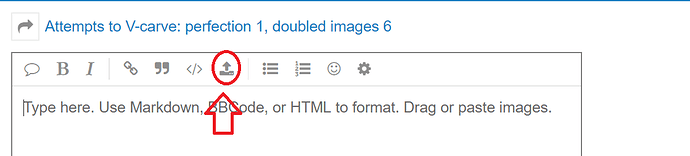

Hey Rod, If you would like someone to look at your work send the c2d and the nc files and im sure someone will look it over.What you need to do to send it is hit the reply button and there is an upload button so you can upload the files, after you select the button press choose files,find your files you want to send and click upload…see the attached image for the upload button

Unfortunately, it’s not likely to be the code.

The great thing about CNC is that the machine will perfectly execute a file when things are working correctly and the entire setup is correct.

The awful thing about CNC is that the machine will take no notice of something having gone wrong or some aspect of setup not being correct and will continue doing things wrong after some small thing has caused things to be off.

For the Shapeoko, that’s most likely belt tension or feeds and speeds — other possibilities include a loose pulley set screw, or binding V wheel:

- belt tension: http://docs.carbide3d.com/assembly/shapeoko/xxl/step-5-belting

- https://precisebits.com/tutorials/calibrating_feeds_n_speeds.htm — note that wood is a natural material and there will be some variability — that’s why this test has one dial back so much from the optimal setting. Also note that the auto feeds and speeds in Carbide Create are more for the Nomad than the Shapeoko

- http://docs.carbide3d.com/shapeoko-faq/shapeoko-3-how-to-check-the-pulley-set-screws/

- http://docs.carbide3d.com/support/tensioning-eccentrics/

One other thing to do is after the test cut, swap out the old endmill for a new one which you are certain is sharp. Where possible, consider identifying your endmills and only using them in a particular material. You can downshift an endmill to roughing or use in less expensive materials when the edge degrades. See http://docs.carbide3d.com/general-faq/machine-operating-checklist/

Thanks, looks like a rebuild is in order. I attached a pic of the issue, FYI. I’ll be in touch as always.

Rod

Looks alot like Will mentioned. A loose set screw in the X.

Looks to me like all your problems are in the X movements.

That narrows it down to one motor, at least.

Many thanks to Will et al, for the responses. Yes, after being lucky enough to find the world’s smallest set screw, I replaced it in the X pully with a little Loctite (as this is the second time). I also adjusted the carriage V-wheels and anything else within shouting distance.

Thank you, thank you

Rod

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.