Here is a quick video highlighting some of the useful bits in UGCS.

Excellent video! Very helpful.

Very helpful video! Any other problems planned in the future?

Problems? I only offer solutions

Have my MD easy set up. One problem having is I can’t seem to figure out how to set up the my Carbide Touch Probe. But I also like to set up some macros to do rapid movements similar to what we have and carbide motion. I have the SP3

G53 is your rapid co-ordinates system i.e. G53 x-100 y-100 z-20

The probe module in UGCS is quite easy to use. I think on Z you need to enter a negative no.

Careful using G53 commands if you’re not familiar. Unless you’ve modified your firmware these will always be negative. Also, G53 is the machine coordinate system, but it is not a motion command. It will use the last modal command for motion (G0 or G1, G0 being the rapid).

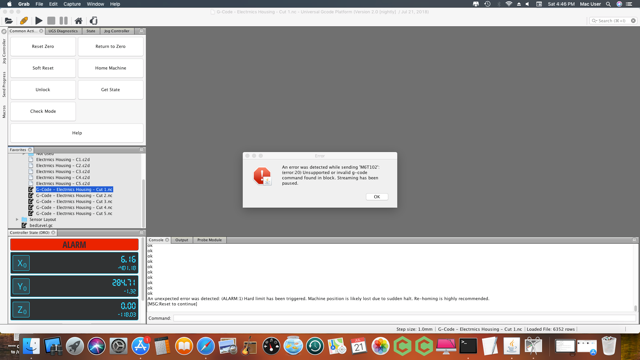

So this happened. Everything was going fine and then suddenly the machine went cray. One more reason cardbide needs to add an e-stop. First experience with UGS was not great.

Really not carbides fault,but you can put your own in.there is a spot on the board to plug it in…https://www.amazon.com/JMAF-Mushroom-Emergency-Button-Switch/dp/B07BCY7HGN/ref=sr_1_11?s=hi&ie=UTF8&qid=1532203807&sr=1-11&keywords=emergency+stop+button

What were you doing?

I was running a relatively simple job.

Carbide remove the pins on the later versions of control board.

Can you use feed hold? Thats what I did on a 2.4 board.

Was not aware of this.There should still be a way to stop the machine in a pinch.Cm has the pause feature that would work as an e-stop im sure ugs has somthing of the sort.you could also keep the inline power switch within arms reach and just kill the power if needed… @WillAdams why did they remove the pins?

Sorry. Somewhat of a newbie. What is free hold?

Ya. I should have had the inline switch in a more accessible place.

NO – PAUSE is NOT a replacement for an estop. The “easy” way to be safe is mount the power switch on the front of the machine so you can hit it easily if there is an issue. A big e-stop button is a better way than that, but requires a little work.

An e-stop isn’t about “oops I set something up wrong” it’s a safety feature.

Pause also won’t stop a command in progress, it waits for the current one to complete - that’s not much help if for example you have a long move in progress (one command) or a too-deep plunge. An real e-stop will. I think feed-stop is supposed to, but someone else needs to confirm that being the case.

The pins not on the board is irrelevant - the place for them is there. It just makes it a little more difficult to do.

Never mind. Miss read your post. I tried to use feed hold but Unfortunately USG was unresponsive. Luckily I have everything connected to a power strip and was able to pull the plug quickly.

Carbide support told me that it is not possible to add an e stop. Happy to know it is in fact possible. I check the boards for advice on how to setup an e-stop.

It is a relevant question as to why the pins are no longer there,mine came with them and it was a simple $8 add on.Dosent make since others now have to do solder work they may not be capable of or even have the tools to do it.Thanks for the info about the pause feature finishing a command in progress.I never use my e-stop as an oops ajustment as you said its there for safety