2000 on x and y, 1000 on z

I recently flash the firmware on SP3!so that I could take advantage of my touch probe and Motion 4. It appears that the firmware update appends XXL setings when it updates the firmware. I concerned this morning by correcting all of my settings and then reruningbthe firmware update. Shure enough my settings reverted back to XXL even thought I running a SP3.

What’s odd is that Motion four seems to deal with the bug internally which is why I didn’t notice it before. Thanks to everyone here for helping me crack the code.

The update -resets- all the settings. If you’re following the directions, it has you resend the SO settings at the end of the process. That wipes out and adjustments you’ve made to bed size. The update also wipes out any belt calibration you’ve done.

I resent the SO settings and there was no change. Maybe I’m doing it wrong, but that still doesn’t explain why motion would work without any issues.

Thank you for all your help. The the HDZ is an amazing. The support you provided before and after sale just blows me away. I look forward to your next product lunch. I will be the first backer in line. I’m hooked on UGCS. That being said, it would be great if Carbide would add support for the HDZ.

Thanks for the kind words Ken. I’m glad you are all up and running now

No problom. Purchased limets switches from your site last night.

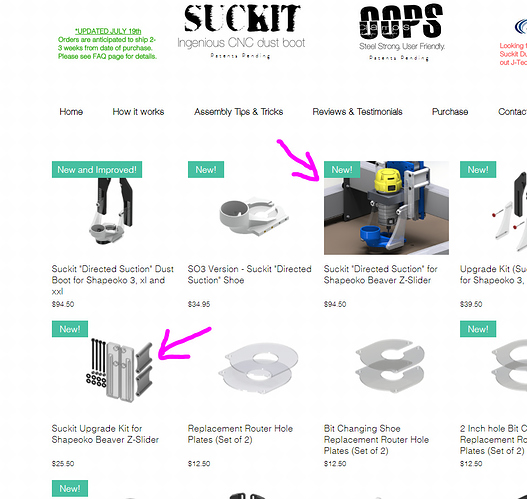

Grab the Oops clamps while your there too,They are amazing.

Awesome, looks like you’re starting to get the hang of things. Keep going.

Thank you. Pretty proud of it for only my second project. Learned a lot about how to trim the machine.

Also Thinking of upgrading my waste board to the aluminum fixture table. The humidity here in DC is wreaking havoc on MDF waste board.

I have a aluminium baseboard on mine - well worth it and I think Carbide 3d one is pretty good value.

As an aside - depending on how gung-ho you’re feeling - it’s completely possible to create your own aluminium base er… board from scratch. You really just need to get a hold of an appropriately sized slab of metal, some drills and taps for the holes you want… and a lot of patience. It can takes ages to hand tap lots of holes in a new base board. Saying that from experience.

That’s what I did. I would say a precision milled would be better mind that way all your holes are perfectly inline with the x and y.

You could slap on a large Ali sheet and have the machine do the work

How true is it The aluminum baseboard as compared to the MDF baseboard. I’ve spent a lot of Squaring up the gantry, tramming the z-axis, and leveling the baseboard. I’m working on a Arduino powered pressure and force meter to help with tensioning the belts equally. My goal is to make machine as accurate as possible.

I can’t speak for aluminum bed flatness, but if you’re on one of the big machines like the XXL, you’ll chase bed flatness caused by flex at the middle of the bed. On mine I ditched the (un)leveling feet and put MDF shims under strategic places. I have pretty much zero bed related Z axis inaccuracies since doing that. Prior to that I could give a firm push and see the bed deflect a good 1/8" at the middle, ran myself in circles prior to making that discovery.

Dan

It’s pretty good, needed to be surfaced. Dan raises a good point.

What I would do is keep your standard MDF bead then make a Aluminium spoil board for ontop i.e. something that is the same size as the cutting area. Use the machine to drill and level it.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.