Bingo! Information uploaded! This is progress. I’ve downloaded Inkscape and I’ll try to see if that works. I figure that by using the shotgun method, sooner or later something will work.

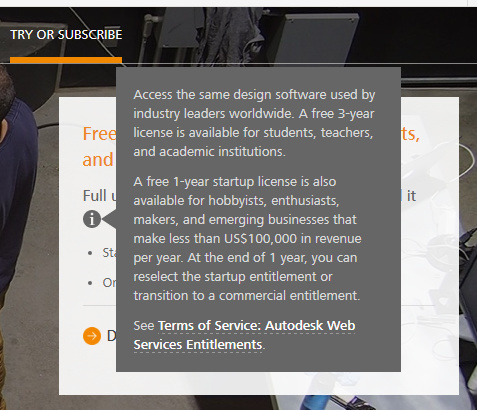

A full 3D CAD & CAM program you might want to try is Autodesk’s Fusion 360. It is free to use provided your company doesn’t make over $100k per year. I have yet to master the CAM end of it, but having about 20k hours of various 3D CAD use, it’s pretty decent.

Chris, it suggests that it’s “as low as $25/mo” but free for students and educators, are you sure it’s free for low-volume companies? I have an old version of Solidworks that I like for doing design but it’s getting ever more dated, and I’ll never afford to upgrade it, so “free” would be rather enticing to switch over and learn something new, especially if it has the CAM stuff built in. I’ve been trying HSMXpress and it seems to work well but I haven’t tried it’s gcode on the shapeoko yet.

Absolutely certain, refer to attached screenshot from their site.

That’s awesome, thanks!

Maybe I finally have a grip on all of this… (?)

(And, I can not thank you all enough for your VAST patience with this old FNG)

-

-

-

- Carbide Create is 2.5D

-

-

-

-

- -I need to have 3D

-

-

-

-

- Shapeoko XL doesn’t care what software creates the work

-

-

-

-

-

- Meshcam is 3D and will work with Shapeoko XL

-

-

Now…if all of that is correct, do I need to send to Carbide Motion in a specific format? If not, what else would I need to FINALLY be able to use my CNC?

CAM programs build G-Code, that is their purpose. The Carbide Motion is simply a “Sender” program. It sends commands to the machine from your g-code file. You can use Carbide Create, Fusion 360, EstlCam, MeshCam, V-Carve, Aspire, etc.etc. to generate your g-code files. Then you can use Carbide motion to send them. Or you can use an array of other sender type programs as well like bCNC, universal g code sender, and many others.

Thank-you! I downloaded Autodesk Fusion 360 that ChiknNutz and you suggested. I got a 1 year free trial. It pulls my files in (huge improvement) but everything loads on its side. Maybe I need to mount the XL on the wall to get it oriented correctly…? JK

I know I’ll have a learning curve to get over, but I am determined to defeat this monster! (But, what the heck…Fusion 360 does actual curves!)

I’m curious to know what this means, and would love to see an example if you have one. I’m an Openscad user as well (started in 3d printing before any CNC).

Basically you convert your image to .PNG format, use the “surface” command to create a heightmap from the .PNG image, and scale appropriately.

https://en.m.wikibooks.org/wiki/OpenSCAD_User_Manual/Other_Language_Features

I looked for a “proof of concept” that I did some

time ago and don’t have it handy.

IIRC, as image resolution goes up rendering time goes up dramatically. So it is important to “pre scale” the image to be no higher resolution than you need for whatever you are making. But I have made small objects with easily recognizable “relief” or lithophane style faces on them.

If I were thinking of doing lithophanes professionally I’d probably look at Vectric, I guess, or maybe Fusion (which I have not used) can do it. But the “surface” command in Openscad does provide heightmaps generated from grayscale images.

I would humbly suggest, Onshape + Kiri:Moto

100% free. Pro grade CAD + CAM. Any platform, , no installs, no downloads etc. Just start using Onshape on any machine in just a few seconds. login in.

Then go to app store and try one of 40 shipping apps, each offering free capabilities. Like Kiri:Moto:

https://appstore.onshape.com/apps/CAM/EAAEWYIOMQKBENEMYW2N7MF253CT4WYL6SUJGEY=/description

This is high end CAD, accessible for all users. If you have ever wanted SolidWorks but couldn’t afford it. Well now you can.

Joe

That looks very capable, but (I say only for myself – YMMV) I am not a fan of cloud apps for my own work product. The “cloudiness” of Fusion’s licensing was the reason I purchased Meshcam for my first CNC, the Othermill, to do 3D machining. I don’t want to put lots of hours of my own time into creating work assets (designs, toolpaths, workflow, etc) that can just be turned off by a change of licensing policy, a decision to orphan a product, or financial troubles on the part of the software developer.

Even if Vectric folds up shop and the Openscad project becomes orphaned, I’ll be able to run my current versions of them - which includes the body of work product I produce for them myself - on virtual machines for decades.

Possession, as they say, is 9/10 of the law. And cloud companies take virtual possession not only of the software installation, but of your ability to use your own work product accumulated over the years that you use the cloud (or even just “cloud licensed” with a cloud-enforced license renewal) product.

For other folks this might not be an issue. But I won’t even look at that kind of cloud product (time spent evaluating products is also valuable) as long as there is any reasonable alternative.

Just to make the point clear, here is an example of the risks involved in buying cloud products at all:

Now consider that with certain kinds of products, for example CAD/CAM, you put hundreds or even thousands of man hours into learning tools, developing workflow, producing your own designs, etc. Even if using the product is “free” there are risks associated with cloud products - including ones like Fusion which periodically check with the “mother ship” for a license as a prerequisite to working at all - which do not obtain with traditional installed / one time license products.

Just something to consider in addition to all of the other factors.

@jfo

If your looking for an example of 2d to 3d hieghtmap, heres this thread on Engraving using meshCAM

Yes, Fusion 360 is free for hobby and low volume commercial. Really.

You don’t need to be a student, but it’s not obvious how you do this. Here are the directions:

That is very cool that Meshcam will make a heightmap from an image. I guess the boundary between CAD and CAM is a bit “fuzzy”.

Hi BoscoBob,

Please, read through all of this a few times. It took me a while to grasp some of the steps.

(READ THROUGH A FEW TIMES)

3 PHASE PROJECT

"Define DESIGN"

For your lithophane project, it seems like the easiest path would be to bring your image file into an App that can edit images first. Make sure you make it to the scale you want. This is the ART part.

Export that file as a .PNG for MESHCAM/MESHCAM PRO.

"Define HOW to MAKE"

Import the .PNG file into MESHCAM.

In MESHCAM you will define how you think it is best to cut out your ART from the material that you have chosen. These are machining strategies, or operations. Basicly, you are defining the tool, its rotational and surface speeds, how it cuts and where, but this is mostly automated. There is a ton of information out there on the internet that can help you define all of this setup stuff. Keep in mind the material you are using, and its thickness as these will need to be considered before you calculate all that stuff I just mentioned.

SET YOUR “0” location at corner, these is where you are defining where the cutter starts and more importantly where it starts to cut out your part.

You will then Export a .NC file for CARBIDE MOTION.

"MAKE"

LOCK YOUR “STOCK” DOWN TO THE SPOIL/WASTE BOARD so that it doesn’t move. Watch many “HOW TO” videos on YOUTUBE and other sites.

Finally, open the .NC file CARBIDE MOTION and use it to send motion commands to your CNC.

There is a lot more to this though and this forum and others will be very helpful.

I hope this clears things up a little without making things more confusing. This is a complicated process at first, it gets easier as you go. I think the idea of doing the example projects is a great piece of advice too.

Enjoy!