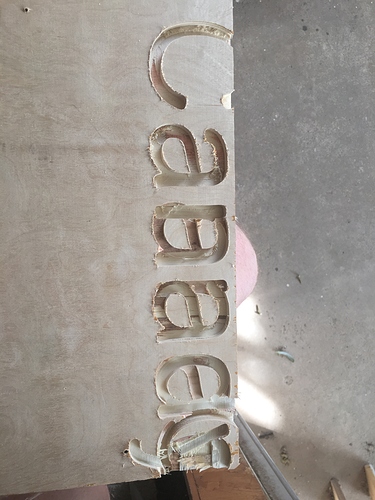

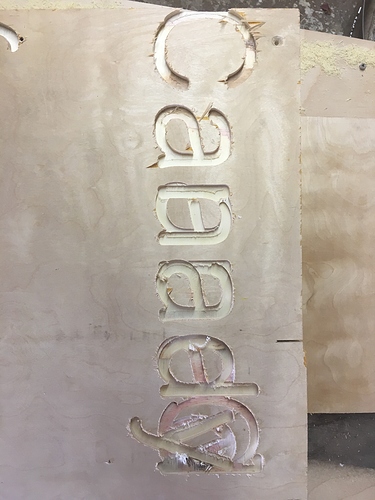

I don’t know what I doing it starts cutting what I created in two different places. Part of this was I put the board in the wrong place. Sorry I new to this whole cnc think.

Could be 99 problems, but I’m betting on operator error. Can you attach you carbide create CAD and CAM (gcode) files, so we can look at them?

canady3.c2d (2.9

canady2.egc (73.5 KB)

Thanks for the file.

Can you tell me where you are setting your X0 and Y0? (for each run)?

I see that you have run it twice, but from different X0 and Y0 locations, so

I was use where ever the homing stops just had my board in he wrong place both times learning as I go

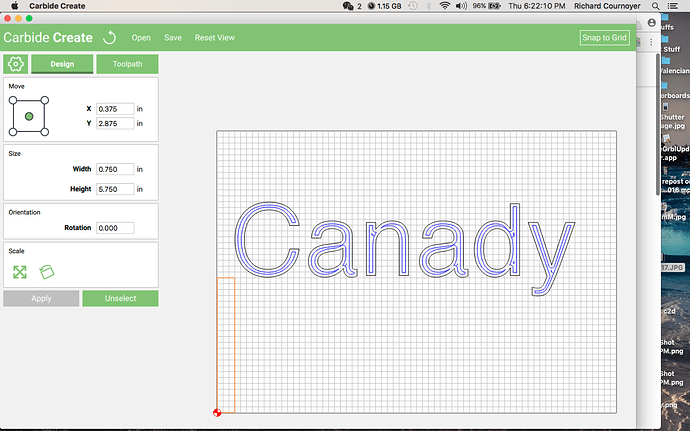

Hmmmm, well Per CC, your X0 is 0.75 inch and Y0 is 5.75 inches from the lower left corner of the first letter (C), see my photo. I don’t think you have a good grasp regarding your X0 and Y0.

The machine (Material) and your CAD/CAM must match perfectly.

PLEASE watch some the training videos. Here is a link:

http://carbide3d.com/carbidecreate/video/

And here is a good article that you also need to ready and study:

http://carbide3d.com/docs/tutorials/tool-change/

Ok I have watched it before but I just rewatched it and it answered all my questions and it showed me what I was doing wrong.