I am looking for a different software to design and run jobs on my Shapeoko 3. I would prefer an all in one software that you can use to design and send G-Code to machine.

@cintigr

Post a picture of what you want to make, and I’ll see how many steps it takes in Carbide Create to make it.

Good News:

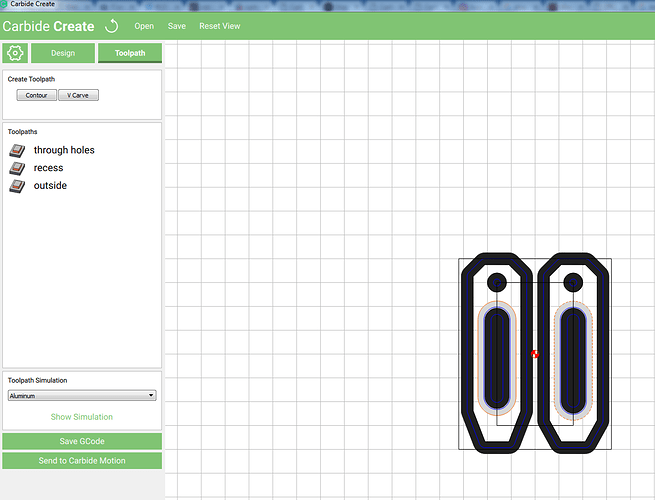

![]()

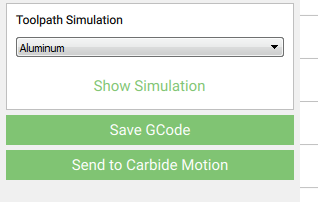

With the newest version of Carbide CREATE, you CAN send Gcode straight to Carbide MOTION.

From the Toolpath screen, you can save the GCODE or Send to Carbide Motion

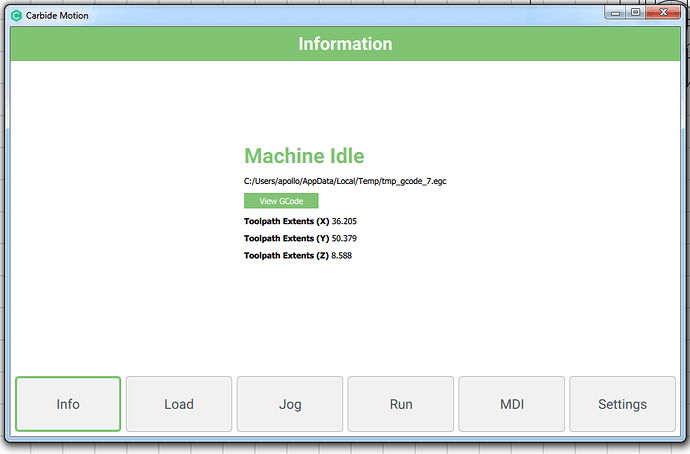

The GCODE from Carbide Create is loaded in Carbide Motion as “Temp/tmp_gcode_7.egc”

List of software with links here: http://www.shapeoko.com/wiki/index.php/Communication_/_Control

Stand-alone possibilities:

- bCNC — has some CAD/CAM functions built-in

- GrblGru — full machine simulator w/ CAD/CAM options

- Inventables Easel — configuration overwrites SO3 defaults, requiring re-setting them

Probably a few others.

That said, while I have a fascination for multi-purpose tools, drawing/CAD, CAM and machine control are very different functions and have markedly different interface requirements and each is arguably better served by a special-purpose app. See http://www.shapeoko.com/wiki/index.php/Software for an overview.

If you could describe what it is you want to do, and how the apps you’ve tried have failed to address your needs maybe we could provide something more specific.

Hi Apollo…

Are new beta versions of Carbide Create pushed the in the same manner Carbide Motion updates are?

My version of CC does not have the ‘Send to Carbide Motion’ feature. My version is Beta 288.

Is that the latest available beta?

Are there release notes available to show known bugs and fixes for versions?

Thanks!

Jefferson

Versio 288 is the current version CC

Make sure you have the current CM (364)

You will need to have both programs open and you are connected to your machine.

In Carbide Motion set your zero and go to LOAD.

Then in Carbide Create in the Toolpath window you will see the “Send to Carbide Motion” option.

I’ll give you a link for your notes request, but if you need some help with something specific, let me know.

http://www.shapeoko.com/wiki/index.php/Carbide_Motion_Machine_Control_Software

Will, you seem to be the one to know how to make the XXL work with Easel. Can you please tell me how to adjust the things so I can cut with the XXL within Easel? I understand the Z axis is different and things need to be reset, but I’m not certain where or how to do that.

I know I can export the G-code but I just want to do it all from one application.

Thank you,

Kevan

I’m afraid I’ve never used Easel — back when it was first announced and I had a beta invite I didn’t have a machine able to run it, and I’ve never liked the idea of cloud software.

My understanding of the current situation is that you shouldn’t do the install / configuration step since it overwrites the Grbl defaults with those of an X-Carve — it may be that the driver software is now tied to the X-Carve controller.

You’re correct; when the application is up, the cutter doesn’t work in CM. If you exit Easel and send xxl data with CM it works again.

So it sounds like I need to be reaching out to the Easel folks in how to send the proper configuration.

Thanks Will

Kevan

What’s the issue you’re having with using Easel?

And… Why do you want to use Easel? It’s pretty limited as a sender.

I cannot cut from Easel; I want to avoid having to save to G file and going to another app.

When I do get it to cut the Z axis is off because of the belt vs the shaft. There must be some sort of way to send a configuration code to fix the z-axis when I am in easel.

I don’t want to know why I should not do this with Easel, I just want to know if someone has done it and how  I really want to design and send to device in the same app, and Easel is easy for what I need it to do.

I really want to design and send to device in the same app, and Easel is easy for what I need it to do.

Thanks, Kevan

Can you post your grbl settings?

In Easel, go to the machine inspector and send $$

Fair enough. I used Easel with my SO3 a couple of years ago, but I don’t recall it changing any of my steps/mm settings.

Neil,

Thank you! That was the ticket. Going into Easel / Machine Inspector and sending the code $120=40 made it work… that enabled me to adjust the Z step so it worked with my Shapeoko XXL.

For everyone else, if you want to use your Shapeoko XXL with Easel, make this adjustment and you can cut from within Easel. I did three different projects and they worked fine… that said, there may be something else that may not work, but mine worked fine.

Thank you again Neil!

Kevan

Would the same code work for the XL? If not what would be the right code for the XL of for that matter the basic SO3?

Yes, that code should work for any Shapeoko which has a belt-drive Z-axis and 40 steps / mm