I bought a 2.8 watt 450nm laser with a control board (ttl) included. Getting it with the board is probably the simplest way to do it. I didn’t find one for sale on Ebay again, but it is similar to this one:

http://www.ebay.com/itm/2-15W-Blue-Light-Laser-Module-450nm-TTL-12V-High-Power-DIY-Metal-Wood-Engraving-/252452884708?var=&hash=item805d0a7c7c

I also bought some safety goggles I could use with the laser. Depending on the wavelength (in my case 450nm), you will have to buy the proper goggles, you can’t willy-nilly pick some goggles. They have to be made to block that wavelength. (good thing I checked) So far, I’m not blind and they appear to work ok, maybe a little dark, but not unuseable.

Goggles I bought: https://www.amazon.com/gp/product/B01DP2HJ0S/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1

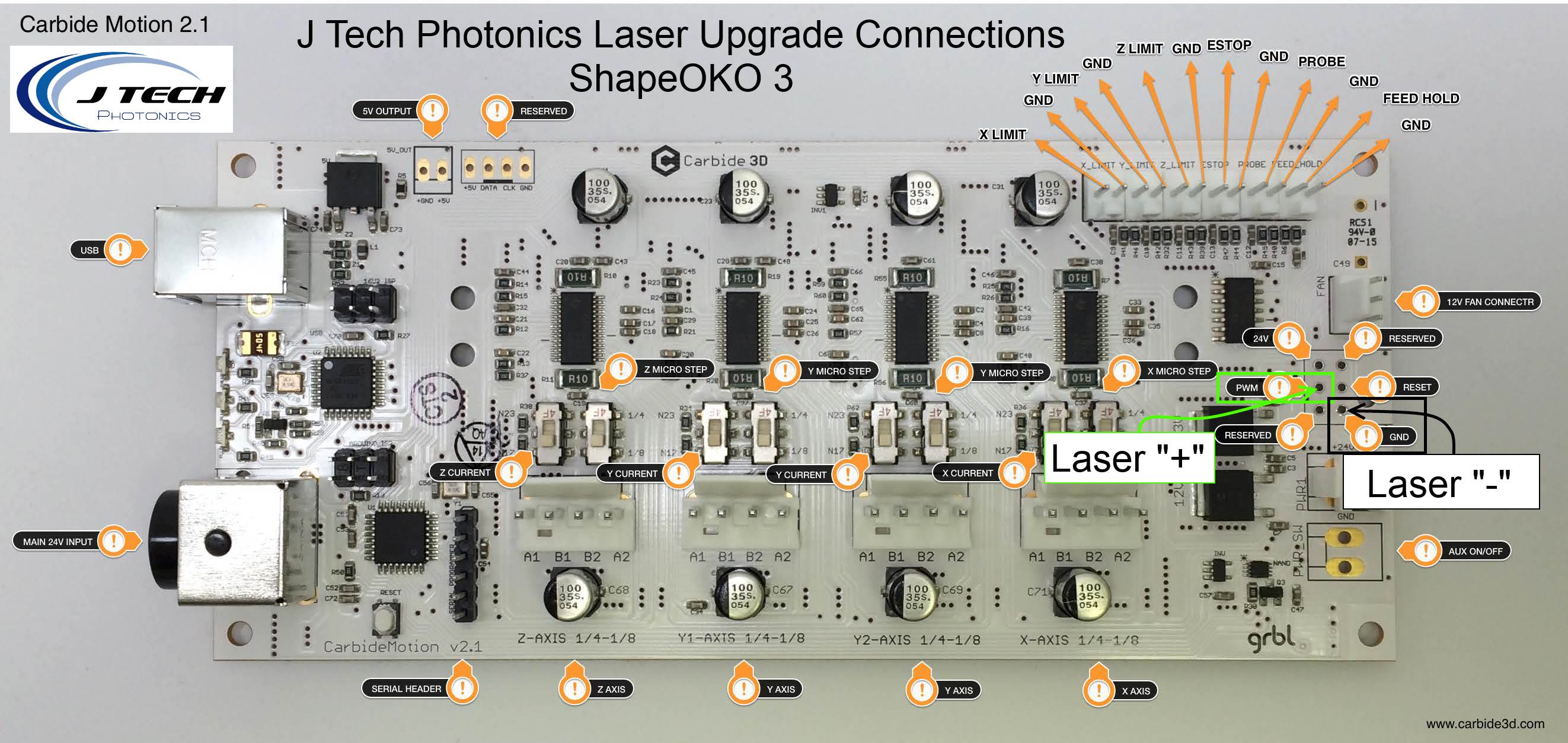

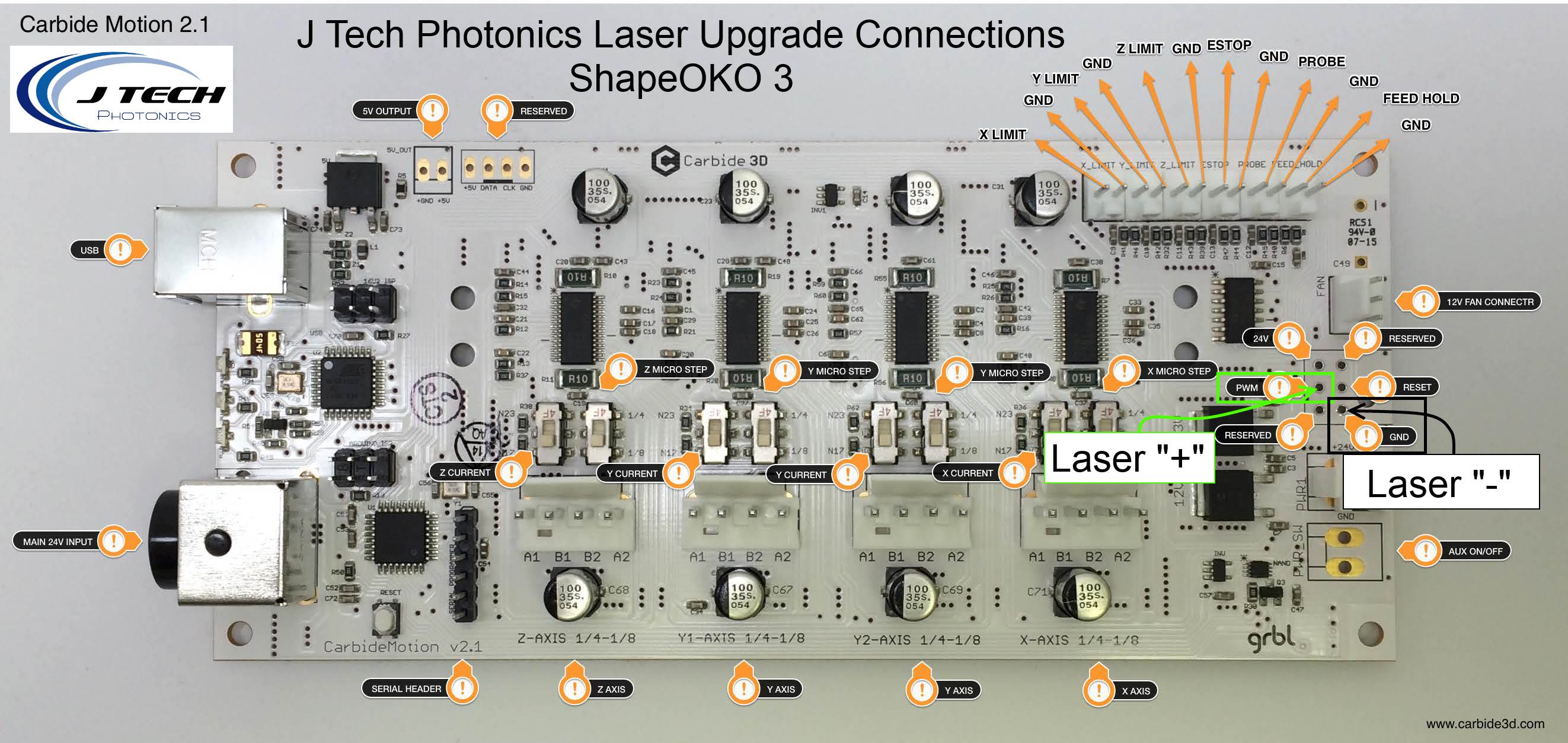

I followed the wiring pictures from the J-Tech website for where to connect the TTL board to the shapeokoo 3. The TTL is connected where it shows “Laser+/Laser-” in the pic/diagram.

This is a link to the pic/diagram:

I haven’t focused it yet, but I completely intend to follow the instructions on the wiki to do that. However, I found a problem with the g code in Sttep 2: The command “g3” I believe should be “M3” and “g5” should be “M5” those are the proper on/off commands. If you want to try more lines to find a focus, then you have to copy/paste more of those lines, changing the y and z coordinates so create a new line while moving it up. Again, I haven’t done this yet, but I loaded the gcode (after I corrected the commands for on/off) so your results may vary.

Wiki Link: http://www.shapeoko.com/wiki/index.php/Laser_Cutter

I downloaded the “Hello World” file for the Shapeoko, and followed the instructions on the Wiki page (Section called “Using the Laser”). It has a link to where you take your shapeoko gcode file and upload it, it spiits out gcode you can use for the laser. When I tried to import the gcode into Carbide Motion, there were errors in the code. There was some unexpected “/” (slash) down in the code in a place or two. Once it was fixed, it seemed to work after I ‘eyeballed’ the focus of the laser (even with goggles, not sure I recommend that). The result is in the video I posted.

So far, I have not re-flashed the control board… am I supposed to?

that’s as far as i’ve gotten, work has been crazy and haven’t gotten back to it yet. Maybe tonight.

Hope this helps.