I have been having some difficulties on my shapeoko for a couple of weeks - all user setup and not enough maintenance.

Essentially one side of my parts would be bigger than the other - the right side would be slightly thicker - maybe by 0.5 of a mm, and if I went right to left I’d get quit a bit of chatter.

I decided to do something about it today - after I scraped my end mill into my bed milling some Ply, - but only on the right side.

After some playing, I discovered I had high and low spots in my solid aluminium bed! now that in it’s self is nothing too crazy so I figured I’d run a finishing pass over it… 0.2mm.

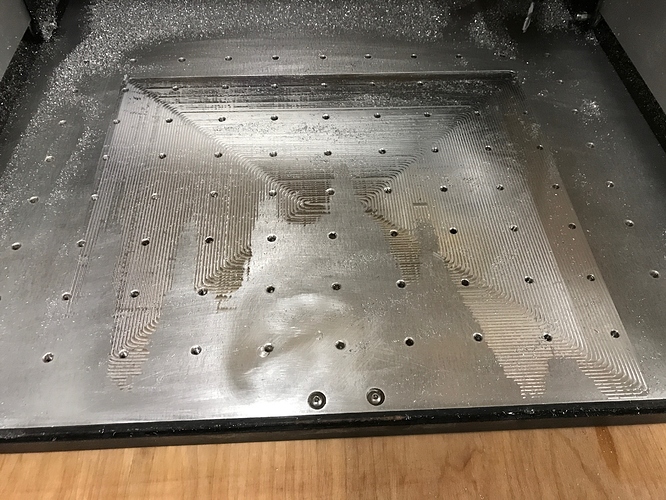

Anyway here are the results

As you can see there are gaps all over the front left. Now the back right has bee milled. Now at this point I should have pulled the S3 out of his box and lifted the rear right side up a little, but I didn’t want to un-do any of the work I had done.

Now onto the chatter, I found my spindle a fraction out. After messing about for 20 min I managed to significantly improve this and now have no chatter going right to left on aluminium.

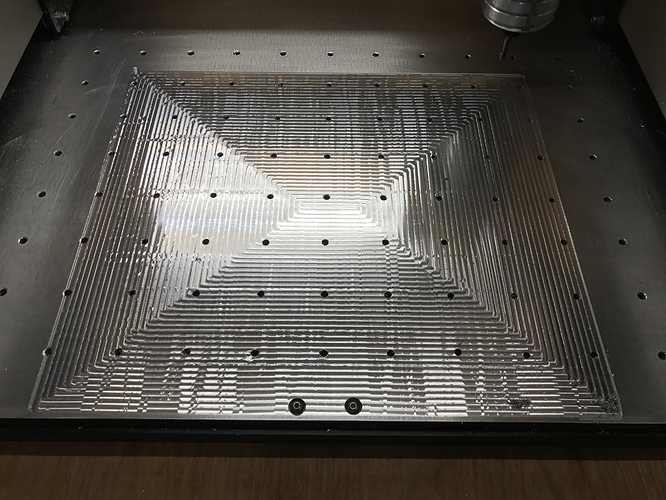

I did another pass.

Again I had a fraction of no contact at the front, so ran another 0.2mm - that cleaned it up and I was left with this.

A lovely (hopefully flat) bed. At the rear right I’ve gone in around 0.7mm I think and 0.3 at the front. But it should be better than before. In an ideal world I’d have surfaced it using a large bit but I only have a 1/4 bit for aluminium.

Anyway, that was my Saturday afternoon.

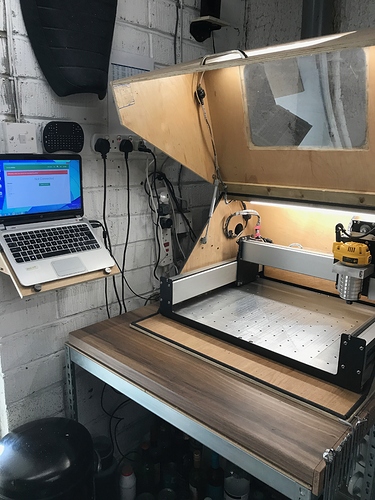

I also mounted my PC on the wall