Nope, no Dobermans, though am looking forward to getting a dog once I’m retired (they don’t allow dogs at work).

Never forget!

For 2 days I’ve been chasing a 0.020" error in my X-Axis. After all the preaching you think I’d first check the SET SCREW!!! Well, it wasn’t so much loose, as fatigued after 2 years of cutting metal.

The point of the set screw had a nice flat on it allowing (only on a load) to slip. In the picture you can see the small dimple from my drilling check (fool me once).

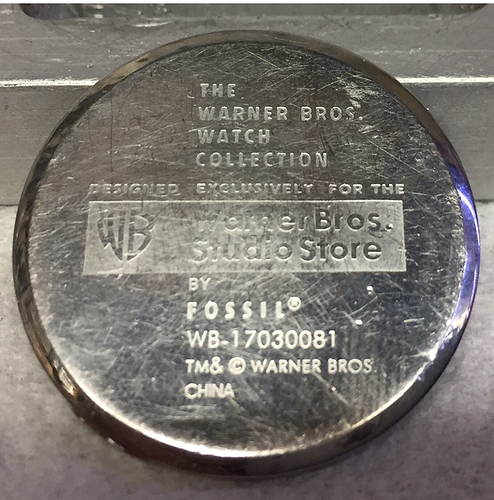

This fixture is two fold. It’ll hold the watch cover still while I engrave the outside and inside as well as a holding fixture to deepen the counterbores another 0.010".

PS I’m also working on my Spotting surface technique

(/uploads/default/original/2X/7/71898a750c7d1ffff34c019a7e1a0726b67de055.JPG)

That spotting technique is cool.

My dad told me about that, once.

I believe one way was to use a wooden dowel and pollish.

How was yours done?

Nice to see that old style being used.

Really great work.

Great work Rich! what type of machining coolant are you using in the bath? I have been reviewing the feeds and speeds calculation to machine 4140. I have a old lawn tractor that they don’t make parts for so I might need to machine a spur gear for the transmission. Any thoughts? Have a great day!

Rob

Thanks.

I’ve machines lots of 4140/4150…and will be working with some in a week or two. My recommendation is to machine it in the annealed (soft) state and then heat treat it to the desired hardness. I know not everyone has this capability (ability). If you need to work within the hard condition…umm, well good luck. Possible? Sure, but it will be a lot slower and tougher on the machine/cutters

Coolant (Amazon)? See the photo. I mix it 10:1.

My material (unfortunately) is already hard, so I will be annealing it, machining it, then rehardening it (tempering it too of course), but that’s the way I roll.

Yea that was my plan to machine it in the annealed state. Thanks for the coolant recommendation.

Interestingly, for super fiddly stuff it turns out using a microscope is practical. First saw it done on the Strange Parts channel on Youtube. eg: https://youtu.be/rHP-OPXK2ig?t=20m32s

The guy there got sick of fiddy stuff too (pre-microscope), and apparently after getting that microscope his hand steadyness improved dramatically. There’s further info on that specific model of microscope too (stereo optics, etc) in case it’s useful:

Getting one is on my wish list, but not sure if it’ll actually happen. ![]()

J,

Strange timing…I was just looking (today) on craigslist. There is a wide selection of stereo microscopes there for $20 to $50…I WILL be picking one up soon.

PS Great minds think alike…lol

R

Oooo yeah. For that price it’s definitely worth experimenting.

Microscopes are a rabbit hole deeper than machine tools. Take a little care before dropping money: do some reading ( https://www.microscopyu.com/ for one) , and be sure to test the instrument out. You might want to drop $US10 on a micrometer slide (a glass microscope slide with a precisely masked set of lines, usually at 10 micron intervals) or a calibration target slide (there are a bunch of designs) to try any candidates with.

Quick intro:

Even at a dead low price, you can go wrong. Doing fine work with uncorrected optics, small exit pupil size, short standoff (how far the image lies above the eyepiece), short working distance (the space between the objective and what you are looking at— nominally the focal distance of the objective, but usually a bit less due to lens rings, shrouds, etc. On some scopes, a lot less), and/or incorrect convergence, is disadvantageous relative to an optivisor.

Things to look for include plan (or plano) objectives-- these have reduces pincushioning/barrel. The term indicates that things that are in a plane LOOK like they are in a plane.

Achromat (better is apochromat) objectives correct for chromatic aberration. Some low end models even today have no correction. They are horrible to work with. Apochromat nulls at three wavelengths, and is nice, but not needed for many applications. Superapo (there are other terms as well) correct at four wavelengths, and are overkill for most industrial applications, like inspections, assembly, etc.

An erect image: Yup, there are some cheapies that produce an inverted image. They are unusable for anything other than entertaining a four year old.

Lighting: a ring light is inexpensive and desirable. LED is fine for most things, and a lot cooler and less expensive than halogen with fibre. Color rendering isn’t great unless you put in a lot of money, but can good, as the devices are not being pushed hard. Generally you will have 32 to 96 LEDs in the ring for uniform lighting.

Single or dual source adjustable is also nice (clean shadows and the ability to control glare in some circumstances), but a dedicated source isn’t really needed for this. The fibre-optic sources are not cheap. A halogen desk lamp does fine for many things. Avoid LEDs in this case-- they will give poor color and odd glare. Here the LEDs will be pushed pretty hard, and good ones are really pricey.

Episcopic (through the objective) illumination is very useful, but not very affordable. This is a feature of the 'scope from the factory (or a stack-in option, like on my Nikon), as it uses a beam splitter to inject the illumination into the optical path. I do not own a unit with this feature, but used such back when I was doing semiconductor fab. here are, obviously, other features I would pay for first unless there is a real need. It also adds elements to the optical path, with the attendant (small) degradation to the image.

Common objective is desirable (versus Greenough, where two objectives are used). You are more likely to get a flat image and less likely to have alignment and convergence issues.

There are advantages to zoom rather than single or turret/switched objectives, but the additional cost is significant.

Avoid high magnification by (the questionable) virtue of high mag eyepieces. 10X (or 7.5X) is a decent overall magnification for hand work and general inspection, and it is preferable that this is a 1X objective and 10X eyepiece. For 20X, a 2X objective and 10X eyepiece, rather than 1X and 20X, gives significantly better resolution. ALL of the resolving power comes from the objective.

There is a ton more to know (I am most assuredly but an egg. I have a number of years of training and experience and a few hundred hours of CEU, but it is not my daily job nor my area of expertise), but it is like any tool: you don’t want to start with a poor tool, or it is worse than not having the tool. I presently own 6 microscopes for various purposes (traveling for fine measurement, two stereo, one a Nikon zoom, the other generic industrial10X and 30X; an older biological with immersion objectives, and a couple direct measuring via reticle). I lust for a Mantis with three or four objectives and a good articulated mount, but the magic hasn’t happened.

EDIT: Oh yeah: I forgot about the 'scope for the lathe. It is on an articulated arm (being rplaced right now, so not mounted). really handy for setting tools, setting stops, internal threading, and dealing with small boring bars. Especially as I get older and blinder

For inspection work, I -adore- my Mantis. Keep your eyes open (and check craigslist) and you can sometimes find these for a pretty reasonable price (The one below isn’t…I got mine for $200). It’s rare, but does happen. Lenses are VERY expensive, so make sure you get a x2 and a x6 or x8. Sometimes you can find “broken” ones that only need a little TLC. The older ones work great, and the newer ones are still $2k. Have a large enough view you can solder SMT under them as well.

Rich if you’re still watching this thread, where did you buy the necked-down drill bits? I’m looking for either some bits like that, or a miniature drill chuck with a 1/4" shank.

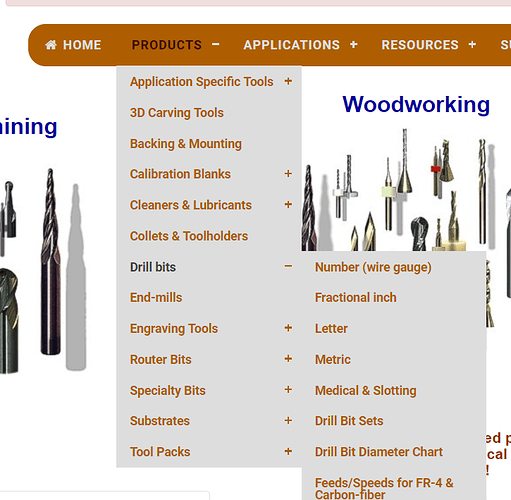

Brian not sure where Rich got those but Precise Bits has many options.

https://www.precisebits.com/gateways/EndMillsHome.htm

RMW

Those might work, but they’re endmills, not drills

I just ordered a small drill chuck so I can use normal straight shank drills. Wanted a 1/4" shank but settled for 3/8".

Amazon (and ebay if I’m not in a hurry)

-Please- don’t put that in a router…

Edit: Didn’t realize the reply was directed about the drill chuck… yeah, I wouldn’t recommend that, I doubt it is balanced for the high RPMs a router runs at, and I’m sure the runout isn’t much better.