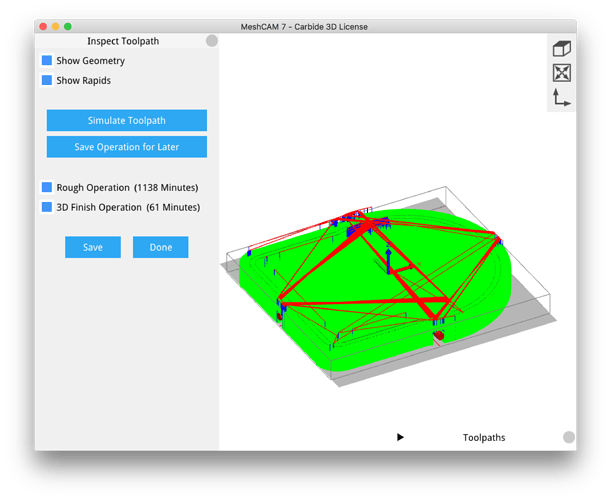

I’m finding the estimated times for Carbide Auto Toolpath (and others) to be impossibly long. A run of 20+ hours… how would you even do that? Am I overlooking something here and/or is there any way to speed this up to a waking-hours timeframe?

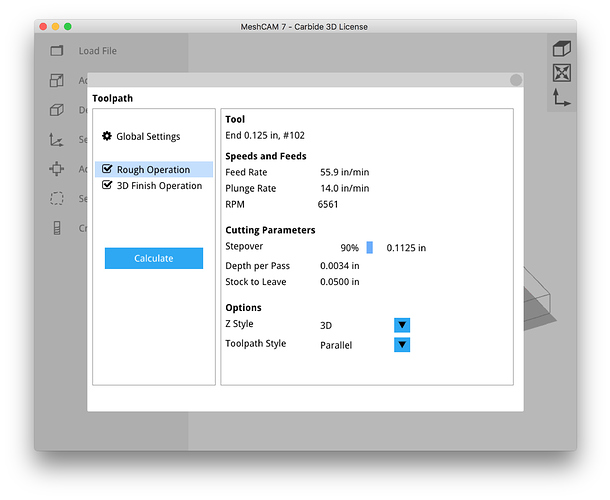

That 3 thousandths depth of cut, with material that needs to have a significant (looks like at least half an inch) is going to take a long time (that’s something on the order of 80 passes). Try doing the roughing with something larger, say .25" square, with a bit more depth of cut (6 thou would cut your time in half even with the 1/8" mill, 6 thou, and a .25" endmill is more like 18 times faster), and it’ll be a LOT shorter. I don’t know what your material is, but .003 is pretty small except for maybe aluminum. I’d also suggest roughing with the square, then doing two separate finishing passes - one with a round endmill to get the curved bits around the edges (set a keep out in the middle), and square for the big flat part in the middle (probably won’t matter much, but could set a keep out over the rounded parts).

As @mikep noted, you want to use a different, larger tool for the first pass.

One way to fake out MeshCAM into doing 3 passes is to set up the first pair of files w/ a large and medium-sized endmill in one file, then in a second file, set up the medium-sized endmill for roughing, and a finishing pass w/ a small one and not emit the medium-sized roughing pass.

Yeah it’s just wood (a thick cheeseboard I’m going to obliterate for practice.) I’ll see what options I have on hand in the larger bite department. I’ve got to get over this fear of snapping all my parts and just go for it. Also, I can’t quite relate to these numbers yet, so thanks for the insight! (These numbers were just the defaults so I’ll play around with them as suggested.)

A side question is about holding down an 8”x8” square of wood. The included double-sided tape doesn’t stick. I’m guessing some sanding will help, but is there a good idea for a “full-bed” stock?

Try a nice clean MDF wasteboard and blue tape on the bottom of the stock, then use cyanoacrylate (super) glue to glue it down — you can use baking soda as an activator.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.