Making some parts out of 1 inch UHMW and the feeds & speeds that come up in Carbide Create seem too aggressive and my Nomad is going into a limit switch fault. Has anyone found good depth of cut, rpm and feed & plunge rates for cutting UHMW using .250 and .125 end mills?

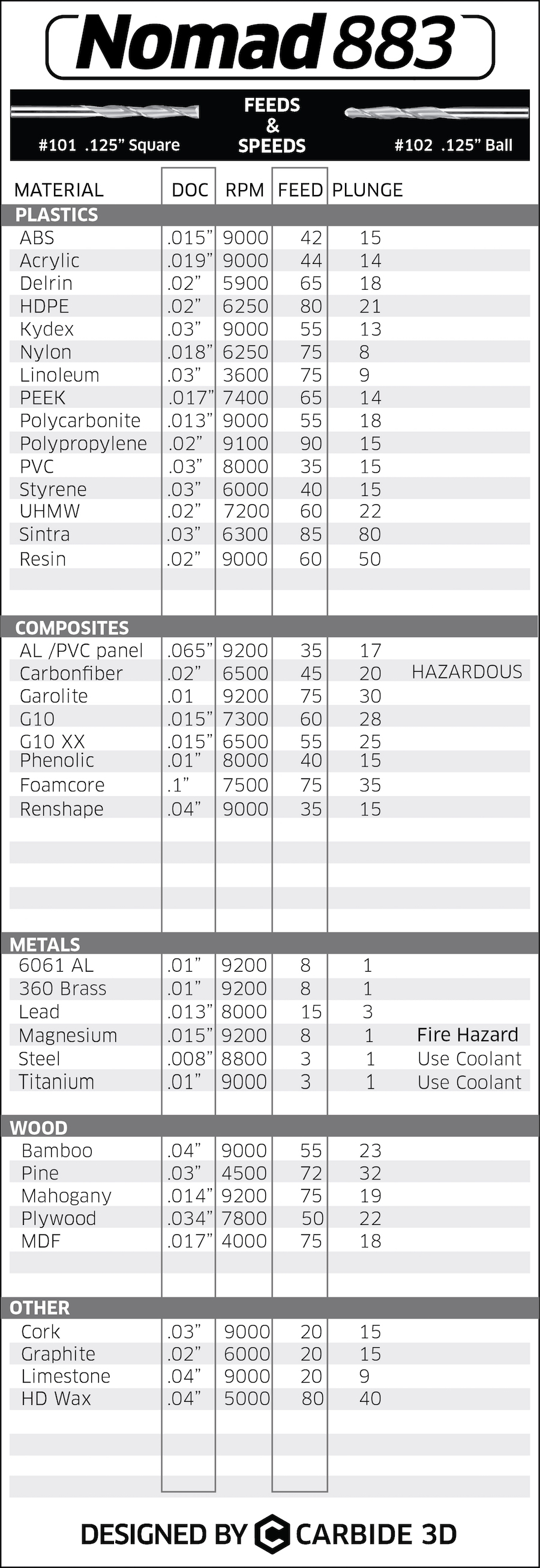

I think you want to start with the numbers here: http://carbide3d.com/nomad/feedandspeed/

Those were tested and produced after the most recent Carbide Create version.

Thanks…I’ll compare to my settings. What unit of measure are the feed rates? I’ve been using inches per minute and the rates on the chart look very different.

They are inches per minute.

Also, those numbers are for the 0.125" 2-flute end mills from Carbide3D. A 0.250" mill will want to go slower and/or shallower, I think.

Is that with about a 50% step over?

I’ve run slots all the way down with numbers on that chart (for other materials), but for finish quality, I like my last cut to have 10% of the cutter width or less. That said, for a square end, I usually set my stepover to 40% of the cutter width.

Parts are milling nicely! Thanks for the help!

The doc has been moved, the new url is: http://docs.carbide3d.com/support/supportfiles/Nomad883_feeds_125.jpg

This is very helpful for a newbie like me evaluating the Nomad 883 Pro. I need to be able to cut Gabon Ebony which is very dense (3080 on Janka scale). With a max rpm of 10,000 do you think the Nomad can handle it and get a smooth cut?

Welcome @aabelman!

Some folks cut aluminium on their Nomad, so ebony should be no problem at all, it’s only a matter of using adequate cutting parameters.

Great! Thanks so much.

Just as a follow-up. Given the Nomad 3 rpm increase, do you think Carbide 3D will come out with a revised speed and feeds chart and update Meshacam, Carbide Create so there is a Nomad 3 option?