I have a Shapeoko 4 XXL and I have noticed that the cutting has been slightly jerky as of late. I had an issue where the machine stopped mid cut and while I was resetting everything, I noticed that the gantry on the right side can be wiggled back and forth with no resistance. The left side however is tight and resists any attempt to wiggle it. Any ideas how I correct this issue and hopefully this solves my jerky cutting?

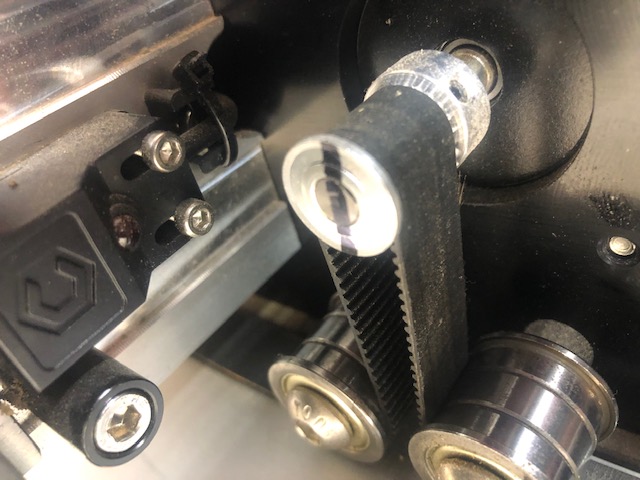

- Check the set screws on the pully, make sure there are two screws, one over the flat of the motor shaft

- If you are comfortable resetting your belts, disconnect the two Y belts. Try to initialize the machine, the Z will rise first, then it will start moving along the X. At that time both Y motors should be spinning. If not, you likely have a wiring problem - contact support.

Ok I think I think I found my issue. When I turn on the power to the unit the left stepper motor engages and does not allow me to move it. The right motor however I can grab with my two fingers and rotate it enough to cause the gantry to move back and forth. The Z Axismotor is like the left one…solid. I think I may need a new Stepper motor so I will call Support tomorrow and verify with them. Thanks Michael.

From what I’ve seen here, an unresponsive stepper motor is much more likely to be a wiring problem than a broken motor.

In particular, you should check all the connectors. Look for loose wires / pins, or any signs of arcing (discoloration from heat).

I’ll double check the wiring and connections as suggested.

Thank you, Michael, for making me go back and have a second look! The wiring and such looked perfect, however I disconnected everything, blew it all out in case there was dust and connected everything again. When I applied power to the motor I could see and hear it engage yet I was still able to slightly turn the motor back and forth. Then I noticed that the stepper motor itself was not in fact turning, only the pulley/gear was! I missed that the first time around, so I tightened the two set screws and wouldn’t you know it, it’s fixed! Now I need to ground my dust collection as I have gotten two shocks from it today and I have a feeling that is what caused me to lose connection earlier today.

Here is a trick I use.

I noticed that in a different thread and I may do the same thing going forward. Thanks for the idea.

I am running the job again to see if the jerkiness is gone…I have to air cut for a bit first…