Luke

November 23, 2018, 9:28pm

1

Hi guys

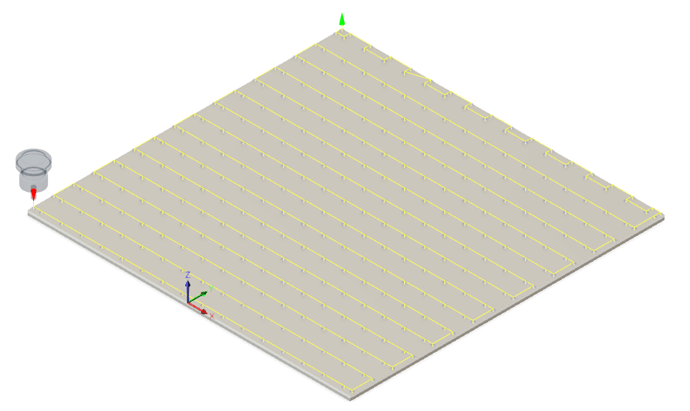

I’ve been working on a baseboard drilling cycle for my home grown cnc, however I think it will also work for an XXL. This is meant for an aluminium base and M6 holes. You set the machine at the front middle and click go.

3 Cam cycles, a round pass to check clearances, 306 holes, then 306 bevels.

They can be downloaded from here:

https://a360.co/2PQ6VyI

2 Likes

neilferreri

November 24, 2018, 12:36am

2

Are you going to tap those by hand or try thread milling them?

Griff

November 24, 2018, 4:44am

3

I hope he decides thread mill…

1 Like

Luke

November 24, 2018, 8:19am

4

I wasn’t going to… but then I can’t think of a reason not to…

If only I had thought about it Monday and I would have bought a thread mill in time for this weekend.

Update, where can I buy one from?

Luke

November 24, 2018, 8:53am

5

Griff

November 24, 2018, 4:30pm

6

https://www.ebay.com/usr/roguesystemsinc?_trksid=p2057872.m2749.l2754

They have threadmills. Not sure about UK shipping

EDIT: Oops, no metric, sorry.

But, ask, maybe they will make some.

1 Like

neilferreri

November 24, 2018, 5:34pm

7

Or you could spend 3/4 weeks DOING the threading.

Luke

November 24, 2018, 5:40pm

8

Ah I can’t wait that long to thread it…

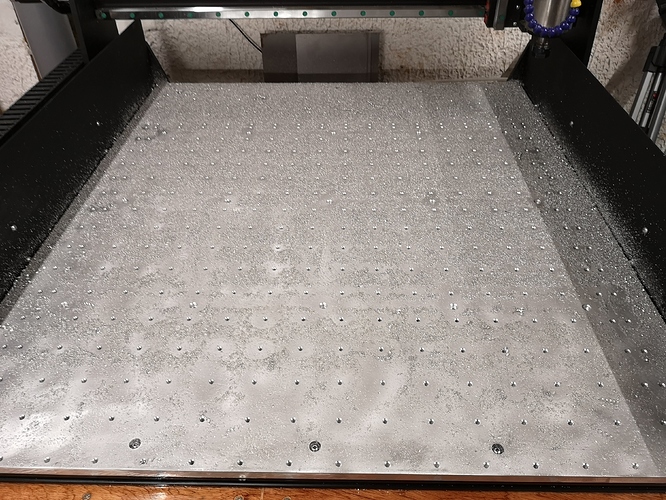

I have now had the machine running for 2/3 hours milling 321 5mm holes, and 15 10mm pockets… then 321 chamfers…

I will save the tapping for tomorrow, I need to lift the board out a fraction…

4 Likes

Luke

November 25, 2018, 5:33pm

9

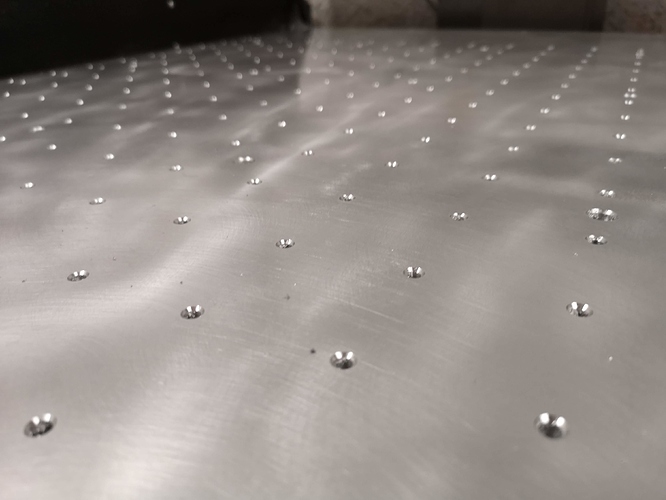

it took me an hour and three dewalt batteries but all my holes are threaded!

time to make something!

4 Likes

system

December 25, 2018, 5:33pm

10

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.