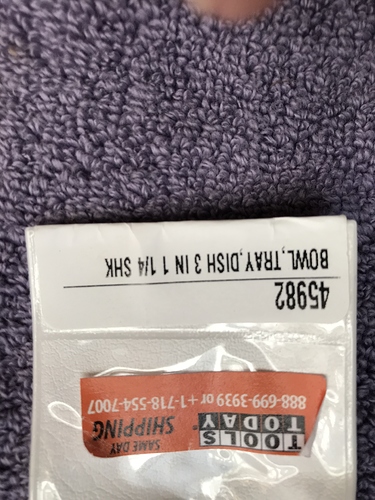

I’m trying my hand at making a men’s valet tray. I’m using the 3/4” bowl/.tray bit from Amana tools. Once the cutting is done there remains lines on the bottom of the recesses and the center is not exactly as deep as the sides. Any help will be great appreciated.

Using specialty and router bits such as that entail a bit of experimentation — they can also be demanding of the machine, so make sure everything is good mechanically first (belt tension, pulley set screws, V wheels, &c.)

Thanks Will. Do you have an alternative suggestion for a bit to use ?

I would suggest using normal ball-nosed endmills where possible — unfortunately, that entails using 3D modeling for all but the most basic of forms — wish there was an easier way to achieve that sort of thing.

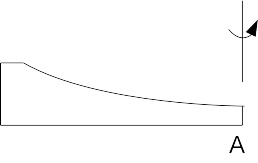

If this is just a standard bowl shape cut into a chunk of wood, I have a Fusion360 file that does this. It was incredibly simple to design…probably a lot easier to do than explain. Draw the profile from the center to the edge and then rotate around point A to form a bowl. I used a 1/4 flat endmill and then a round endmill and a couple of the 3D toolpaths availalble in F360.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.