A few things to remember about any wood product…

Wood is a living, breathing thing. Even after it’s chopped down and dried out and definitely dead, it still behaves as a living, breathing thing. Dead wood will continue to expand and contract, warp and twist, forever. Or until it decomposes into it’s constituent molecules.

Plywood, as a process and as a product, compensates for most of the more wily properties of wood, but it has never been a perfect process. And the companies that make plywood have never promised a perfect product. When it comes to building a project that requires wide, flat panels, plywood is by far a much better, easier to work with, more reliable method for getting wood to be flat than any other method.

Like a fingerprint, every tree is different. Even among the same species. Every part of a tree is different.

Even if you go down to individual cells, they’re all just a little bit different. It’s not like metal or plastic, where it’s all one homogeneous mass of matter. Plywood manufacturing uses machinery that can’t perfectly adapt to all of these differences. That machinery is designed to get as much good material out of the tree as possible, which, in some cases, may not be a whole lot.

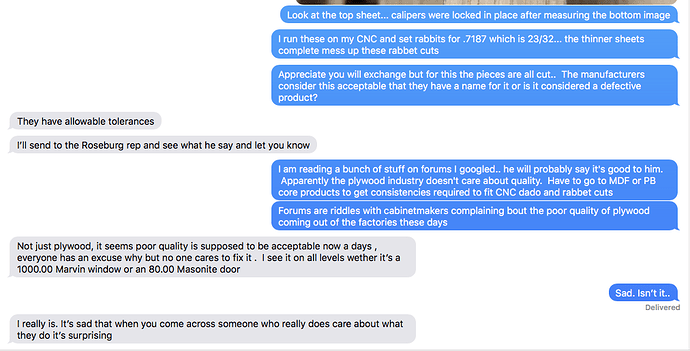

Some companies are better than others. They produce a higher quality product, but with that comes a higher price and usually less availability. It takes time to implement the kind of quality assurance you’re asking for. Time being money makes quality more expensive. It’s also harder to find high quality plywood because they don’t make nearly as much of it as the cheap stuff. They don’t make as much high quality plywood because fewer people are willing to pay for it.

I don’t think it’s a question of companies “not caring” about the quality of their products. Its more of a question of customers not being willing to pay for the better quality stuff. Is it frustrating when you can only find low quality Chinese made plywood at the big box store? Sure it is. But a whole lot of people out there are buying it up like crazy. If I were a plywood manufacturer and my A grade plywood is sitting on the shelves, waiting for a discerning customer to come along, and my C grade plywood is flying off the shelves, of course I’m going to make more of the cheap stuff. I might even limit my distribution of the A grade plywood to a few specialty stores where I know it’s actually going to sell, and use that shelf space at the big box stores to put even more cheap plywood out there.

The other issue is that you’re putting this plywood on a machine that’s accurate within a few thousandths of an inch (or better depending on how much time you’re willing to use to dial it in) and expecting the plywood to match that level of accuracy. There’s no plywood on the planet that’s going to be that good. MDF comes close, but still… To say that it’s because plywood companies just “don’t care” about their product any more is completely absurd. It sounds to me like you just need to adjust your expectations to the material that you’re using. If your dados are coming out to wide, adjust your program and recut or glue in some thin strips of wood to make up the difference. If you dados are too narrow, then break out the sanding blocks. All joinery, regardless of whether it’s made by CNC or power tools or hand tools, requires fit up and adjustment. The plywood manufacturer can’t do anything to help you with that.