@Cereza

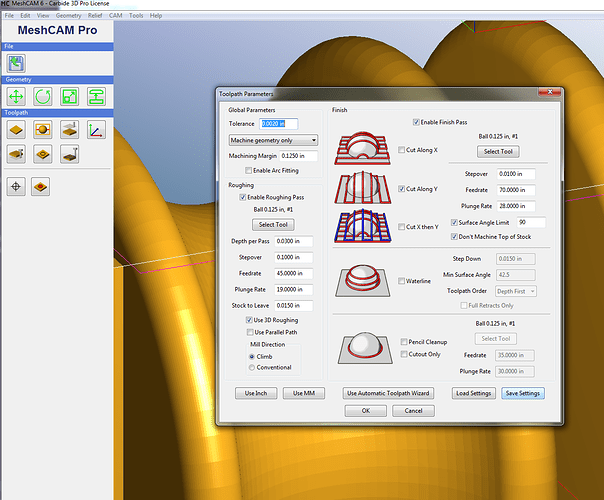

To reduce the run time on your part I used some of the MeshCAM options and then adjusted the Toolpath settings for maximum effieciency, however I do always recommend a test cut in scrap material if possible.

-

I scaled the part in meshCAM to get it under the 3" Z limit.

The Scale factor was .9 -

I used a keep out area to limit the machining area and run time.

-

The Tool Path is set to machine “Geometry Only” to reduce machine time as well.

( I think in Standard when setting up toolpaths, but you can toggle the units to MM if you prefer)

Heres the MeshCAM file for your reference.

two Rollers.mcf (1.9 MB)

Heres the Tool Path Settings file for you to load.

hdpe 3d 125 ball.tps (2.1 KB)

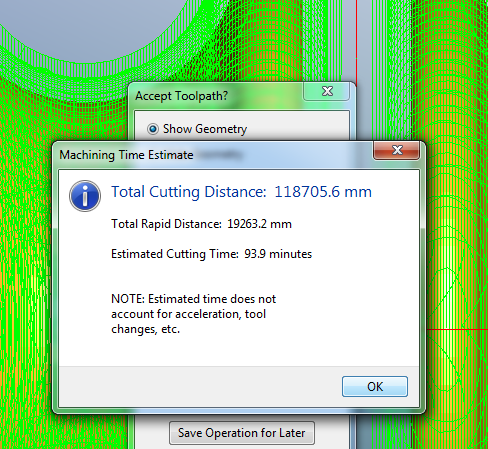

I set this up for HDPE and got the machine time to 1.5 hour per side.

No tool change required, the .125 ball is used for the roughing and the finish pass.

(For your final part in ABS you may need to reduce the DOC of the Roughing pass from .030" to .015")

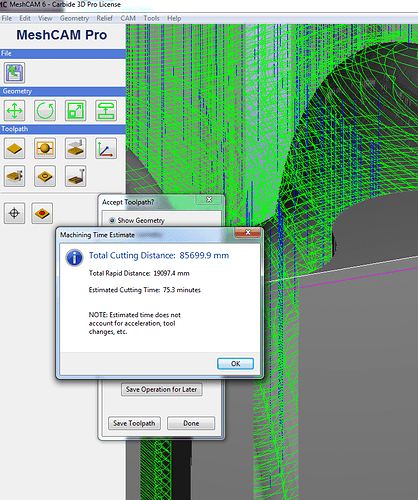

Run Time Estimate

The Roughing pass is the majority of the job due to the orientation of the parts.

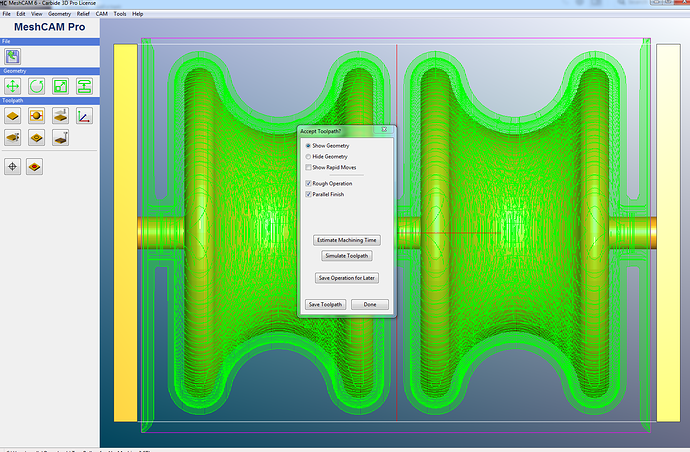

Note the orientation of the Parralel pass, and absence of a waterline pass due to the orientation.

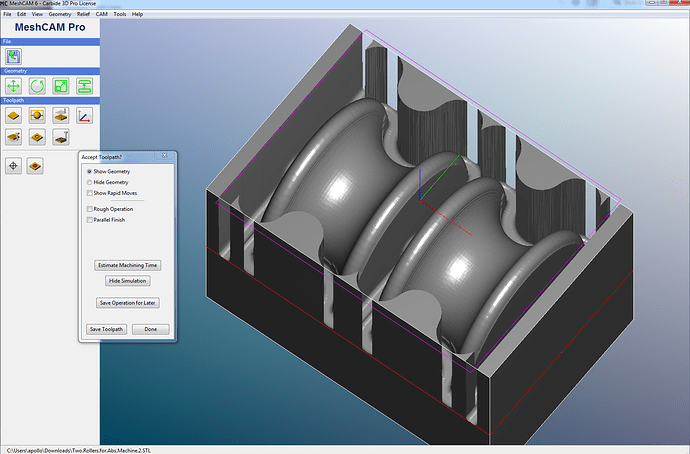

“Geometry Only” will only reveal the parts, and save run time.

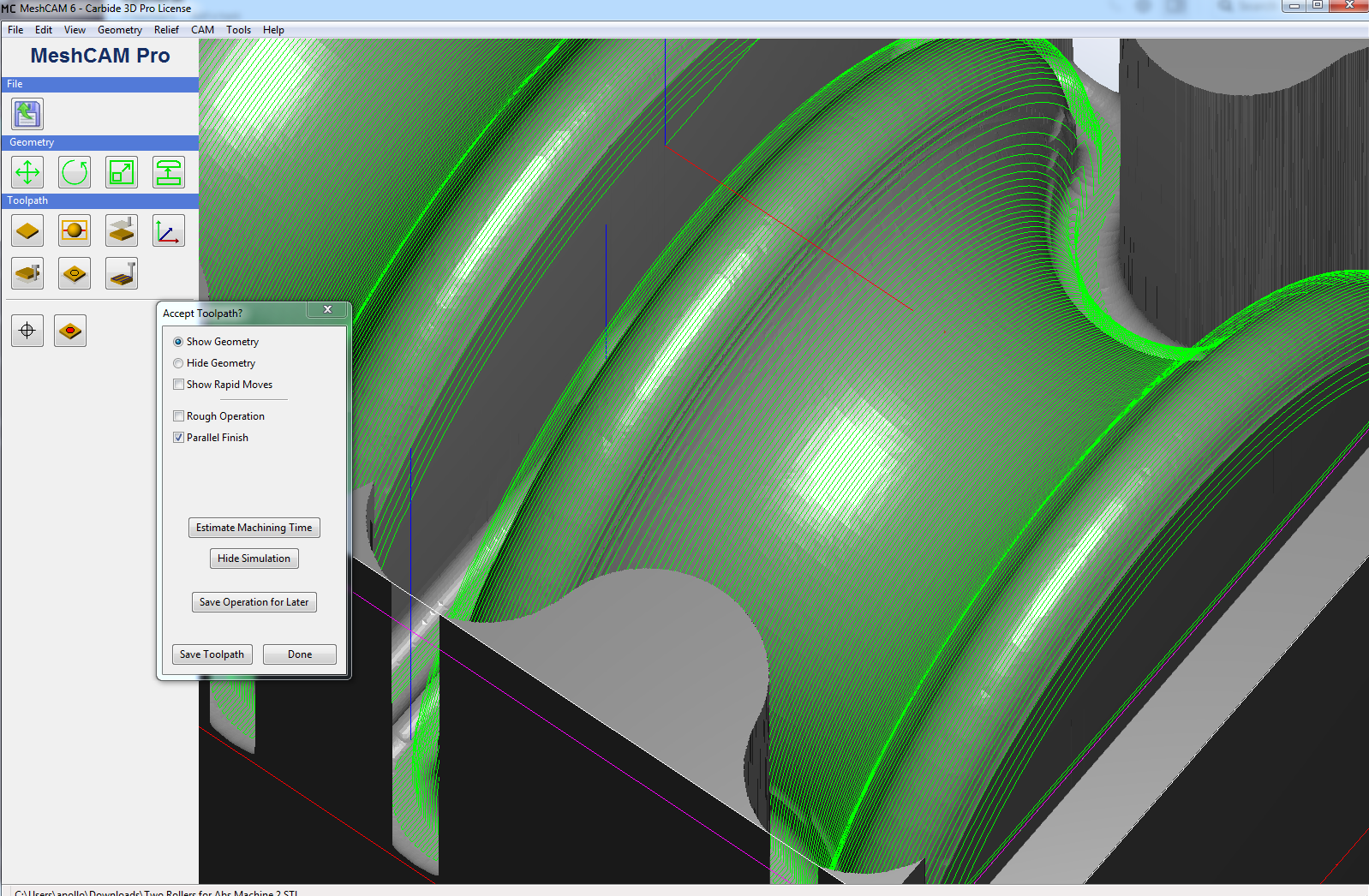

Toolpath View

The Purple rectangle is a “Keep-out” area, This may be able to be further adjusted to save run time.

Currently it is allowing meshCAM to read the walls adjacent to the wheels, which is extra run time.

Parralel Finish pass

Here you can see the Finish pass is oriented in the Y axis direction to respect the wheel radius geometry.

-A