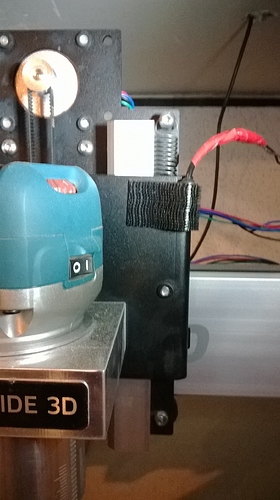

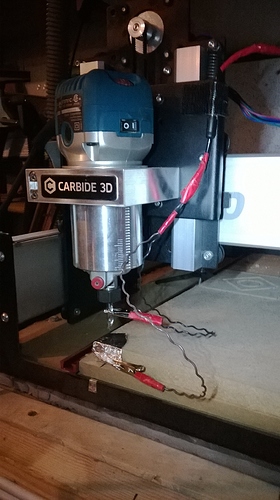

Finally I am up and running with my Shapeoko 3 ! Got the probe working, doing edge finding, setting my Z , and tool measurements after tool changes, Using Estlcam to control the cutting and it works great. Brought the svg into Estlcam and immeciately set tool paths, inside cut, outside cut, shallow drill holes to center mark screw locations. Boy does that MDF make dust. The 1st cuts are for the dust boot. The 1/8" flat cutter’s feed and speed on the wiki seemed a bit slow, but I’m not experienced enough to know if it’s too slow. The bit did start to get hot so that’s my indication. Used 0.43 DOC, 32 mm/sec feed and 8 mm/sec plunge. I loaded my probe setup pics, I used a mini jack from headphones and connected it to the Z plate so I can unplug it to not have it in my way.

I cut the circle square triangle test first and came out with 0.005 precision, that’s good enough for now, need better setup tools to get it closer and better eyes to see the caliper scale. Thanks