timtom1

November 12, 2016, 11:03am

1

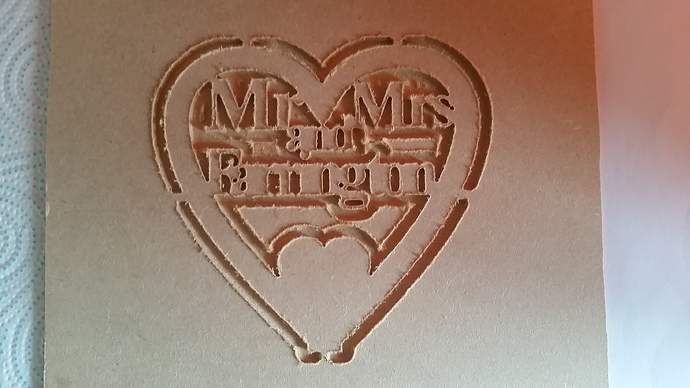

So I’ve been asked to produce a wedding cake topper on my nomad.

But its not cut all the parts out. I’m using a 0.125" ball end and a 0.63" ball end for finishing.

Heart 2.STL (442.4 KB)

I’m using a scrap piece of wood for testing 3mm MDF waste board

The end result

The 0.63" is missing the fine detail which I thought it would do?

Help please

Tim

drichard

November 12, 2016, 11:54am

2

Tim,

Tim,

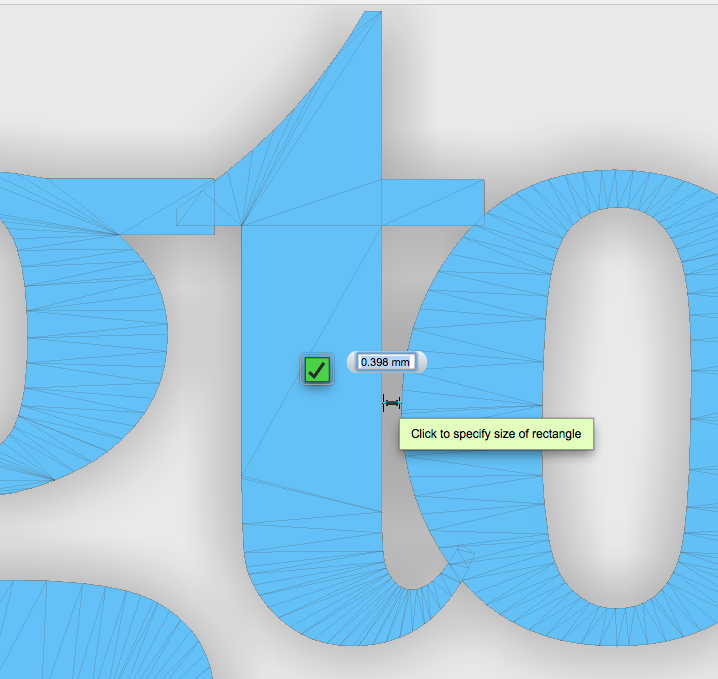

The areas that are not cutting are due to the fact that they are smaller than your smallest end mill. (See Photo).

I recommend that you use a 1/32" ball end mill (But they don’t have must LOC, so you can’t cut very deep with them.

There are still areas where it won’t cut because it will still be less than 1/32 but you will get a lot more detail than you have now.

Maybe if the customer allows it you could scale the model up (make it larger)

timtom1

November 12, 2016, 2:25pm

4

Yeah sorry 0.063"

That makes sense I will try and scale it up and see if that works. Thanks for the advice guys

1 Like

timtom1

December 7, 2016, 8:34pm

5

I’ve now bought a 0.032" ballnose tool #121 but just posted a new topic on what settings would I require?